Transport line frameworks are generally utilized in different enterprises to proficiently move merchandise and materials. Furthermore, with regards to guaranteeing the smooth working and sturdiness of these frameworks, aluminum profiles assume a significant part. In this article, we will dive into the different parts of aluminum profiles in transport line frameworks, investigating their importance, benefits, types, contemplations for choice, and establishment and support methodology. Beginning with an outline, we will comprehend what aluminum profiles are and the way that they are incorporated into transport line frameworks. Then, at that point, we will investigate the significance of these profiles in upgrading the general exhibition and life span of the frameworks. Furthermore, we will examine the various benefits that aluminum profiles offer, like their lightweight nature, erosion opposition, and adaptability. Besides, we will dig into the various kinds of aluminum profiles utilized in transport line frameworks, including T-space profiles, level profiles, and round profiles, among others. Taking into account the large number of choices accessible, we will likewise give bits of knowledge on the elements to consider while choosing aluminum profiles for explicit transport line frameworks. Finally, we will exhibit genuine contextual analyses of effective executions of aluminum profiles in transport line frameworks. Toward the finish of this article, perusers will have an extensive comprehension of the meaning of aluminum profiles in transport line frameworks and be furnished with the information to pursue informed choices in regards to their establishment and support.

Overview of Aluminum Profiles

Aluminum profiles are a fundamental part in different businesses, offering a large number of utilizations and advantages. These profiles are produced using aluminum, a lightweight and flexible metal that has phenomenal erosion obstruction. The flexibility of aluminum profiles permits them to be utilized in areas like development, transportation, gadgets, and furniture fabricating.

One of the critical benefits of aluminum profiles is their toughness. Because of the inborn properties of aluminum, these profiles can endure cruel natural circumstances without crumbling. This makes them ideal for outside structures, like windows, entryways, and drapery walls, where protection from enduring is critical. Moreover, aluminum profiles have a high solidarity to-weight proportion, making them reasonable for supporting weighty burdens while limiting the general load of the design.

One more critical advantage of aluminum profiles is their plan adaptability. These profiles can be effortlessly expelled into different shapes and sizes, considering modified arrangements that meet explicit necessities. Whether it's a complex engineering plan or a basic structure, aluminum profiles can be custom-made to fit the ideal determinations. This adaptability additionally stretches out to completions and varieties, empowering planners and architects to make outwardly engaging designs.

Notwithstanding their solidness and adaptability, aluminum profiles are additionally harmless to the ecosystem. Aluminum is an exceptionally recyclable material, with almost 75% of all aluminum at any point created still being used today. The reusing system requires just a small part of the energy expected to create essential aluminum, pursuing it a reasonable decision. By using aluminum profiles, businesses can add to decreasing their carbon impression and advance a greener future.

Importance of Aluminum Profiles in Conveyor Belt Systems

Aluminum profiles assume a urgent part in transport line frameworks, and their significance can't be neglected. These profiles are explicitly intended to offer help and construction to the transport lines, guaranteeing smooth and proficient activity in different ventures.

One of the critical benefits of utilizing aluminum profiles in transport line frameworks is their lightweight nature. Aluminum is known for its high solidarity to-weight proportion, settling on it an optimal decision for developing transport line outlines. The daintiness of these profiles not just decreases the general load of the framework yet additionally takes into account more straightforward establishment and support.

One more huge advantage of aluminum profiles is their erosion opposition. Transport line frameworks frequently work in unforgiving conditions, for example, mining or food handling enterprises, where openness to dampness, synthetic substances, and outrageous temperatures is normal. Aluminum's regular oxide layer goes about as a defensive boundary against erosion, guaranteeing the life span and toughness of the transport framework.

Aluminum profiles additionally offer fantastic adaptability and flexibility. They can be effortlessly modified and custom fitted to meet explicit necessities, like different belt widths or tendencies. This adaptability takes into account the effective usage of room and guarantees that the transport framework can adjust to changing creation needs.

Besides, aluminum profiles add to the general productivity and execution of transport line frameworks. Their smooth surface completion diminishes grinding, bringing about less mileage on the belts. This, thus, limits margin time and upkeep costs. Also, the lightweight idea of aluminum profiles decreases the energy utilization expected to work the framework, making it all the more harmless to the ecosystem.

Advantages of Aluminum Profiles in Conveyor Belt Systems

Aluminum profiles assume an essential part in transport line frameworks, offering a few benefits that pursue them a well known decision in different businesses. One of the essential advantages of using aluminum profiles is their lightweight nature. Contrasted with different materials, for example, steel, aluminum profiles are essentially lighter, making them more straightforward to deal with and transport. This benefit not just diminishes the general load of the transport framework yet additionally empowers more straightforward establishment and upkeep.

One more benefit of aluminum profiles in transport line frameworks is their excellent solidarity to-weight proportion. Regardless of being lightweight, aluminum profiles show exceptional strength, permitting them to endure weighty loads and keep up with underlying trustworthiness after some time. This strength is fundamental in transport frameworks, as it guarantees the smooth and proficient development of products without compromising the general steadiness of the framework.

Notwithstanding their solidarity, aluminum profiles offer brilliant consumption obstruction. This property is especially critical in transport line frameworks that might be presented to unforgiving natural circumstances, like dampness or synthetic compounds. Dissimilar to materials like steel, aluminum doesn't rust or erode, guaranteeing the life span and strength of the transport framework. This protection from erosion additionally decreases the requirement for regular upkeep and substitution, bringing about cost investment funds for organizations.

Besides, aluminum profiles are exceptionally flexible and adjustable. They can be effectively molded and intended to meet explicit prerequisites, taking into consideration the making of transport frameworks customized to individual necessities. Whether it's a bended transport or a perplexing game plan, aluminum profiles offer adaptability in plan and format, empowering effective material taking care of and item transportation.

The utilization of aluminum profiles in transport line frameworks likewise has ecological advantages. Aluminum is a recyclable material, and involving it in transport frameworks advances supportability and lessens squander. Furthermore, the energy expected for the development of aluminum profiles is extensively lower contrasted with different materials, further adding to a greener and more eco-accommodating methodology.

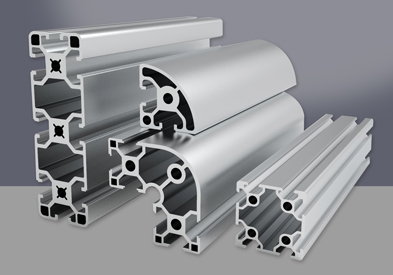

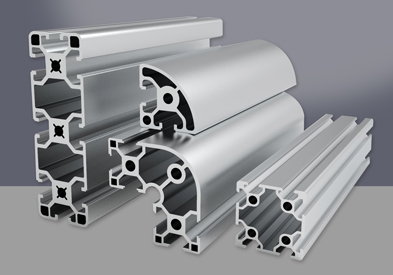

Different Types of Aluminum Profiles Used in Conveyor Belt Systems

Aluminum profiles are a fundamental part in transport line frameworks, as the need might have arisen for effective material dealing with. These profiles are produced using top notch aluminum amalgam, which offers strength, solidness, and consumption opposition. There are various kinds of aluminum profiles utilized in transport line frameworks, each intended for explicit applications and necessities.

One normal sort of aluminum profile utilized in transport line frameworks is the T-space profile. This kind of profile includes a T-molded space along its length, considering simple and adaptable connection of different frill and parts. T-space profiles are frequently used to make custom transport frameworks, as they offer adaptability with regards to plan and arrangement.

One more sort of aluminum profile ordinarily utilized in transport line frameworks is the C-channel profile. This profile is described by its C-molded cross-segment, which gives great bowing and torsional inflexibility. C-channel profiles are regularly utilized for supporting weighty loads and are much of the time found in applications where strength and security are pivotal.

Notwithstanding T-space and C-channel profiles, there are additionally H-divert profiles utilized in transport line frameworks. H-channel profiles have a rectangular shape with an empty place, making them lightweight yet powerful. These profiles are great for applications where weight decrease is really important without settling on strength and sturdiness.

Besides, there are additionally Z-direct profiles utilized in transport line frameworks. Z-channel profiles have an interesting Z-formed cross-segment, which offers expanded primary honesty and burden bearing limit. These profiles are regularly utilized in rock solid applications and are known for their outstanding strength and protection from twisting.

Considerations for Choosing Aluminum Profiles in Conveyor Belt Systems

With regards to picking the right aluminum profiles for transport line frameworks, there are a few key contemplations that should be considered. The kind of aluminum profile utilized can incredibly influence the general presentation and life span of the transport line framework.

One significant component to consider is the strength and sturdiness of the aluminum profiles. Transport line frameworks are ordinarily likely to weighty burdens and steady development, so it's urgent to choose profiles that can endure these circumstances. Aluminum profiles that are produced using excellent materials and have major areas of strength for a plan are great for guaranteeing the life span of the framework.

One more thought is the weight and adaptability of the aluminum profiles. Lightweight profiles can assist with diminishing the general load of the transport line framework, which can bring about expanded productivity and lower energy utilization. Also, profiles that offer adaptability can consider more straightforward establishment and upkeep of the framework.

Notwithstanding strength and weight, the consumption obstruction of the aluminum profiles is additionally a significant component to consider. Transport line frameworks are frequently presented to different natural circumstances, like dampness, synthetics, and temperature variances. Picking aluminum profiles that have magnificent consumption obstruction can assist with forestalling untimely wear and harm to the framework.

Moreover, the plan and similarity of the aluminum profiles ought to be considered. The profiles ought to be viable with the particular necessities of the transport line framework, including its width, length, and burden limit. Also, the plan of the profiles ought to take into account simple reconciliation with different parts of the framework, like rollers and supports.

Installation and Maintenance of Aluminum Profiles in Conveyor Belt Systems

Aluminum profiles assume a vital part in transport line frameworks, guaranteeing smooth and effective material dealing with. The establishment and support of these profiles are fundamental for the ideal working of the transport framework.

During the establishment cycle, it is critical to painstakingly choose the right aluminum profiles that meet the particular prerequisites of the transport line framework. These profiles are accessible in different shapes and sizes, considering customization in light of the application and burden limit. The establishment ought to be done by experienced experts who grasp the complexities of the framework and can guarantee appropriate arrangement and steadiness.

Normal upkeep is imperative to drawing out the life expectancy of aluminum profiles and keeping up with the general presentation of the transport line framework. This incorporates routine reviews to recognize any indications of wear, harm, or misalignment. It is significant to resolve these issues speedily to forestall further harm and keep away from exorbitant fixes or free time.

Cleaning the aluminum profiles is one more basic part of upkeep. Aggregation of soil, trash, or different pollutants can prevent the smooth development of the transport line and influence its general effectiveness. Customary cleaning utilizing suitable cleaning specialists and techniques is important to eliminate any development and keep up with ideal execution.

Notwithstanding support, grease is fundamental to limit rubbing and guarantee smooth activity. Applying greases to the aluminum profiles can lessen mileage, expand their life expectancy, and work on the general productivity of the transport line framework. It is essential to utilize ointments suggested by the maker and follow the predefined stretches for oil.

Legitimate taking care of and stockpiling of extra aluminum profiles are likewise significant. These profiles ought to be put away in a perfect and dry climate to forestall consumption or harm. They ought to be maneuvered carefully to abstain from any bowing or misshapening that could influence their presentation.

Case Studies: Successful Implementation of Aluminum Profiles in Conveyor Belt Systems

Aluminum profiles have demonstrated to be a unique advantage in the execution of transport line frameworks. Through broad contextual analyses, it has become clear that the fruitful joining of aluminum profiles in these frameworks has prompted superior effectiveness, sturdiness, and in general execution.

One vital benefit of utilizing aluminum profiles in transport line frameworks is their lightweight nature. Dissimilar to conventional materials, for example, steel, aluminum profiles offer a critical decrease in weight, bringing about lower energy utilization and expanded efficiency. This weight decrease takes into account quicker transport speeds and diminished mileage on the framework, at last prompting cost investment funds for organizations.

Notwithstanding their lightweight plan, aluminum profiles additionally gloat extraordinary strength and toughness. This settles on them an ideal decision for transport line frameworks that are exposed to weighty burdens and consistent use. The high solidarity to-weight proportion of aluminum profiles guarantees that the framework can deal with the requests of different businesses, including assembling, planned operations, and mining.

Moreover, aluminum profiles give adaptability in planning transport line frameworks. They can be effortlessly tweaked and adjusted to fit explicit necessities, considering consistent mix into existing activities. This adaptability empowers organizations to improve their transport frameworks and amplify effectiveness, eventually prompting expanded efficiency and benefit.

One more huge benefit of utilizing aluminum profiles in transport line frameworks is their consumption obstruction. Dissimilar to different materials, aluminum profiles are exceptionally impervious to rust and consumption, even in brutal conditions. This opposition guarantees the life span of the framework, limiting support expenses and margin time.

Conclusion

In conclusion, aluminum profiles have become an essential component in modern manufacturing due to their lightweight nature, aesthetic appeal, and eco-friendliness. They are preferred by architects, engineers, and designers for enhancing energy efficiency and improving the performance of various industries. The advantages of using aluminum profiles in conveyor belt systems are numerous, including their lightweight nature, exceptional strength-to-weight ratio, corrosion resistance, versatility, and environmental benefits. Incorporating aluminum profiles into conveyor systems can enhance efficiency, reduce costs, and contribute to a sustainable future. Different types of aluminum profiles offer customization and optimization of the system's performance, providing benefits such as strength, durability, and flexibility in design. Choosing the right aluminum profiles for conveyor belt systems requires careful consideration of factors such as strength, weight, corrosion resistance, and compatibility. Regular inspections, cleaning, lubrication, and proper handling are crucial for the efficient operation of conveyor belt systems. Overall, the successful implementation of aluminum profiles in conveyor belt systems has revolutionized the industry, improving efficiency, durability, and overall performance.