Aluminum profiles have become progressively famous in different businesses because of their various benefits and adaptable applications. To completely comprehend the capability of these profiles for your next project, it is critical to dive into their attributes. This article intends to give an extensive outline of aluminum profiles, covering their actual properties, producing cycles, types and assortments, as well as their great many applications.

First and foremost, investigating the actual properties of aluminum profiles is fundamental to decide their appropriateness for explicit tasks. Aluminum profiles are known for their lightweight nature, making them simple to deal with and transport. Furthermore, they show extraordinary consumption opposition, guaranteeing toughness and life span even in brutal conditions. In addition, aluminum profiles have brilliant warm and electrical conductivity, causing them ideal for applications that to require effective intensity dispersal or electrical conduction.

Continuing on, understanding the assembling cycles of aluminum profiles reveals insight into their quality and attributes. The assembling of aluminum profiles commonly includes expulsion, which takes into account the making of complicated shapes and many-sided plans. This cycle guarantees exact aspects and high primary respectability, giving unwavering quality and consistency in the end result. Besides, aluminum profiles can go through different surface medicines, for example, anodization or powder covering, to upgrade their appearance, consumption opposition, and solidness.

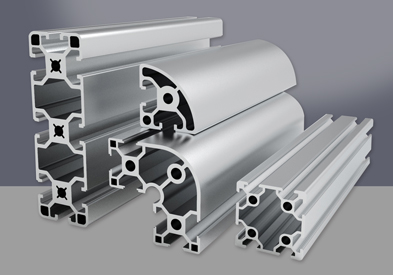

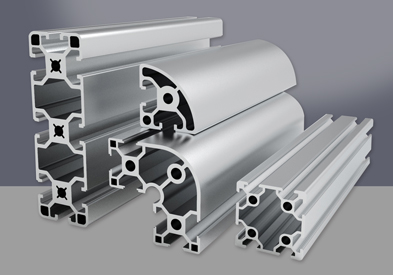

Then, investigating the sorts and assortments of aluminum profiles opens up a universe of opportunities for various ventures. Aluminum profiles are accessible in a great many shapes, including square, rectangular, round, and custom profiles to suit explicit necessities. Furthermore, they come in various combinations, like 6061 and 6063, each offering novel mechanical and compound properties. The accessibility of different surface gets done, tones, and examples further improves the flexibility of aluminum profiles.

At last, understanding the utilizations of aluminum profiles gives knowledge into their far and wide use across businesses. These profiles are broadly used in the development business for window outlines, drapery walls, and underlying scaffolding frameworks. They are additionally ordinarily tracked down in car producing, aviation, gadgets, and transportation areas. Their lightweight yet strong nature goes with them an ideal decision for applications that require strength, solidness, and plan adaptability.

All in all, appreciating the qualities of aluminum profiles is vital for effectively integrating them into your venture. By inspecting their actual properties, producing cycles, types and assortments, too as applications, you can pursue informed choices and outfit the maximum capacity of aluminum profiles. Whether it is for development, auto, or some other industry, understanding these qualities will empower you to proficiently accomplish ideal outcomes and meet your venture prerequisites.

Physical Properties of Aluminum Profiles

Aluminum profiles are broadly utilized in different ventures because of their excellent actual properties. These profiles are produced using aluminum, a lightweight and solid metal that offers various benefits. One of the vital actual properties of aluminum profiles is their high solidarity to-weight proportion. This truly intends that regardless of being lightweight, these profiles are areas of strength for amazingly can endure weighty burdens. This property makes them ideal for use in development and designing applications where strength is pivotal.

One more significant actual property of aluminum profiles is their erosion obstruction. Aluminum normally shapes a flimsy oxide layer on its surface when presented to air, which goes about as a defensive obstruction against rust and consumption. This makes aluminum profiles exceptionally impervious to natural factors like dampness, saltwater, and synthetic substances. Thus, these profiles have a more drawn out life expectancy contrasted with different materials, decreasing support costs and expanding their general sturdiness.

As well as being erosion safe, aluminum profiles are additionally exceptionally moldable. This implies that they can be effectively molded and framed into different setups, making them reasonable for many applications. Whether it's for building window outlines, entryway outlines, or primary parts, aluminum profiles offer adaptability in plan and can be redone to meet explicit necessities.

Moreover, aluminum profiles display fantastic warm conductivity. They productively move heat, making them appropriate for applications where heat scattering is significant. This property is especially advantageous in the hardware business, where aluminum profiles are utilized for heat sinks to chill off electronic parts and forestall overheating.

Ultimately, aluminum profiles are likewise non-attractive, making them reasonable for use in touchy electronic hardware where attractive obstruction is a worry. This property guarantees that the profiles don't influence the exhibition or usefulness of the gadgets they are utilized in.

Manufacturing Processes of Aluminum Profiles

Aluminum profiles have turned into a necessary piece of different ventures, because of their uncommon strength, toughness, and flexibility. These profiles are generally utilized in development, auto, aviation, and numerous different areas. Be that as it may, have you at any point considered how aluminum profiles are fabricated? In this article, we will investigate the assembling processes engaged with making these momentous items.

The most vital phase in assembling aluminum profiles is the determination and readiness of the unrefined substance. Aluminum ingots, which are produced using bauxite mineral, are liquefied in a heater at high temperatures. This liquid aluminum is then moved to a holding heater, where guaranteeing a homogenous composition is continually mixed.

When the liquid aluminum is prepared, it is moved to a projecting machine. In the projecting system, the liquid metal is filled a form, which is generally produced using steel. The form is painstakingly intended to make the ideal shape and aspects of the aluminum profile. After the liquid metal cools and sets, the shape is opened, and the recently framed aluminum profile is taken out.

Then, the aluminum profile goes through an interaction called expulsion. In this cycle, the profile is constrained through a bite the dust, which is a uniquely planned opening. The strain applied during expulsion assists shape the aluminum into the ideal cross-sectional with profiling. The expelled profile is then cut into the ideal lengths.

After expulsion, the aluminum profiles go through different completing cycles. One of the most widely recognized completing cycles is anodizing. Anodizing includes submerging the profiles in an electrolyte arrangement and passing an electric flow through them. This makes an oxide layer on the outer layer of the profiles, which improves their consumption opposition and gives an embellishing finish.

Another completing interaction is powder covering. In this cycle, a dry powder is electrostatically applied to the outer layer of the profiles. The covered profiles are then restored in a stove, where the powder melts and structures a strong defensive layer. Powder covering improves the presence of the profiles as well as gives great climate obstruction.

Types and Varieties of Aluminum Profiles

Aluminum profiles are a fundamental part in different businesses and applications. These profiles are flexible and can be altered to suit explicit plan necessities. From development to transportation, aluminum profiles offer various advantages and are liked for their solidness, strength, and lightweight nature.

There are different sorts and assortments of aluminum profiles accessible on the lookout. One of the most well-known types is the expelled aluminum profile. This sort of profile is made by warming aluminum billets and compelling them through a bite the dust to get the ideal shape. Expelled aluminum profiles are known for their fantastic solidarity to-weight proportion and can be found in a scope of shapes like points, channels, and T-segments.

Another well known type is the underlying aluminum profile. These profiles are explicitly intended for load-bearing applications and are ordinarily utilized in development projects. They are known for their high strength and unbending nature, making them ideal for building outlines, support structures, and design components.

Aluminum profiles additionally come in different surface completes the process of, including anodized, powder-covered, and factory finish. Anodizing is a cycle that improves the consumption opposition of the aluminum and gives an embellishing finish. Powder covering, then again, includes applying a dry powder to the outer layer of the profile and afterward relieving it under heat, bringing about a sturdy and alluring completion. Factory finish profiles, then again, have a smooth, untreated surface that can be additionally redone according to the prerequisite.

The flexibility of aluminum profiles stretches out to their applications too. These profiles are ordinarily utilized in the development business for window outlines, entryways, drape walls, and material frameworks. They are likewise generally utilized in the transportation business for the assembling of car parts, for example, body boards, skeleton, and inside manages. Also, aluminum profiles find applications in the hardware business for heat sinks and walled in areas, as well as in the modern area for transport frameworks and machine outlines.

Applications of Aluminum Profiles

Aluminum profiles, generally perceived for their adaptability and toughness, track down applications in various enterprises. From development to transportation, these profiles have changed the manner in which we construct and plan different designs and items.

In the development business, aluminum profiles assume a pivotal part in making lightweight yet solid structures for structures. Their outstanding solidarity to-weight proportion pursues them an optimal decision for building exteriors, windows, and entryways. With their consumption safe properties, these profiles are additionally utilized in the development of scaffolds and other framework projects, guaranteeing life span and wellbeing.

The auto business likewise benefits significantly from the utilization of aluminum profiles. With the consistent drive for lighter and more eco-friendly vehicles, makers go to aluminum profiles for their primary parts. These profiles empower the making of lightweight vehicle bodies and suspension, improving eco-friendliness and lessening emanations. Also, the inborn recyclability of aluminum pursues it a harmless to the ecosystem decision for the auto area.

One more striking utilization of aluminum profiles can be tracked down in the assembling of furniture. The flexibility of aluminum permits fashioners to make smooth and present day pieces that are both stylishly satisfying and useful. From seats and tables to racking units, aluminum profiles offer vast potential outcomes with regards to plan and customization. Moreover, the lightweight idea of aluminum makes furniture simpler to move and adjust, taking care of the developing requirements and inclinations of buyers.

In the domain of gadgets, aluminum profiles find use in the creation of intensity sinks. These profiles effectively scatter heat created by electronic parts, forestalling overheating and guaranteeing ideal execution. The warm conductivity of aluminum pursues it an incredible decision for heat sink applications, as it successfully moves heat away from touchy hardware.

Aluminum profiles likewise have a critical presence in the environmentally friendly power area. Sunlight based charger edges and mounting frameworks frequently use these profiles because of their consumption obstruction and primary honesty. By giving a solid and strong help structure, aluminum profiles add to the productive saddling of sun powered energy.

Conclusion

In conclusion, aluminum profiles are highly sought after in various industries due to their desirable physical properties such as high strength-to-weight ratio, corrosion resistance, malleability, thermal conductivity, and non-magnetic nature. These properties make them versatile and suitable for diverse applications in construction, engineering, electronics, and other sectors. The manufacturing processes of aluminum profiles involve several steps to ensure that the final products meet required specifications and exhibit desired properties. Aluminum profiles continue to be in high demand for their strength, durability, and versatility, making them an essential component in various industries. They offer a wide range of options in terms of types, varieties, and finishes, and their lightweight nature makes them a preferred choice for designers and manufacturers. The applications of aluminum profiles are vast and diverse, ranging from construction and automotive industries to furniture manufacturing and renewable energy. With their unique properties and versatility, aluminum profiles contribute to innovation and sustainable development in various sectors.