Aluminum profiles have turned into a fundamental part in the field of robotization gear, tracking down colossal applications across different ventures. Offering various advantages, these profiles give a flexible answer for planning and developing mechanization frameworks. In this article, we will investigate the upsides of utilizing aluminum profiles in mechanization hardware and dig into their different applications. Genuine contextual investigations will be introduced to exhibit the common sense and viability of aluminum profiles. Moreover, we will examine significant contemplations for choosing the right aluminum profiles for robotization gear, as well as give experiences into their establishment and upkeep. While aluminum profiles offer huge benefits, we will likewise address the difficulties and restrictions related with their utilization. At last, we will investigate future patterns and advancements in aluminum profiles that are set to reform the mechanization gear industry.

Benefits of Using Aluminum Profiles in Automation Equipment

Aluminum profiles have turned into a fundamental part in the computerization gear industry, offering a huge number of advantages. These lightweight and solid profiles have upset the assembling and gathering processes, giving various benefits to organizations across different areas.

One of the critical advantages of utilizing aluminum profiles in mechanization hardware is their excellent solidarity to-weight proportion. Aluminum is famous for its high strength, which permits it to endure weighty burdens while staying lightweight. This trademark makes it an optimal material for building robotization hardware, as it guarantees primary solidness without adding superfluous weight.

Notwithstanding their solidarity, aluminum profiles offer fantastic erosion opposition. Dissimilar to different metals, aluminum doesn't rust when presented to dampness, making it profoundly solid and enduring. This erosion opposition is especially pivotal in robotization gear, which frequently works in brutal conditions or comes into contact with fluids and synthetic substances. By using aluminum profiles, makers can guarantee that their gear stays practical and dependable, even in testing conditions.

One more benefit of aluminum profiles in computerization gear is their adaptability. These profiles can be effectively altered and machined to meet explicit plan prerequisites. This adaptability permits producers to make perplexing and complex designs, advancing the exhibition and usefulness of their mechanization gear. Whether it's making tweaked outlines, transport frameworks, or automated arms, aluminum profiles offer vast opportunities for plan development.

Besides, aluminum profiles are exceptionally financially savvy. The underlying interest in aluminum profiles might be higher than different materials, however their drawn out benefits offset the underlying expense. Aluminum's sturdiness and protection from consumption diminish support and substitution costs, bringing about tremendous expense reserve funds over the long run. Also, the lightweight idea of aluminum diminishes postage costs, pursuing it a monetarily suitable decision for mechanization gear producers.

Applications of Aluminum Profiles in Automation Equipment

Aluminum profiles have turned into an essential piece of robotization gear in different enterprises. These flexible profiles offer many applications, settling on them an ideal decision for producers and architects the same. With their uncommon solidarity to-weight proportion, strength, and adaptability, aluminum profiles have reformed the plan and usefulness of robotization hardware.

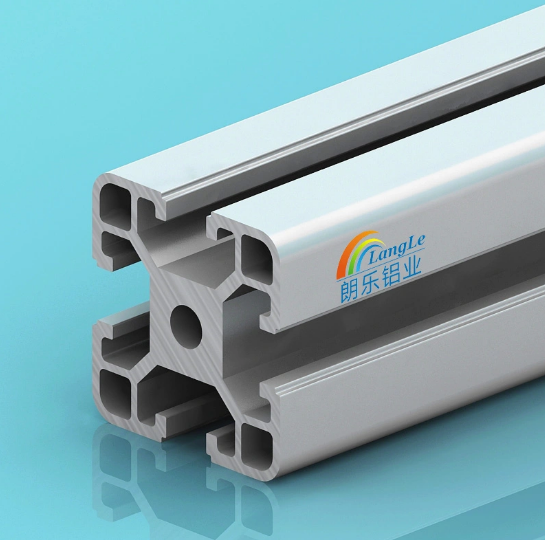

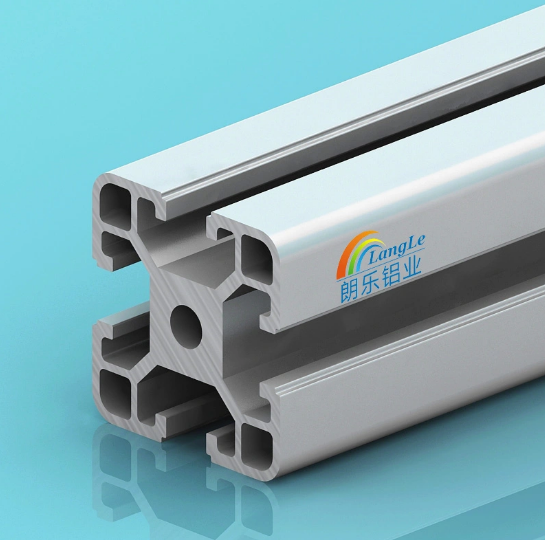

One of the essential uses of aluminum profiles in robotization gear is in the development of edges and designs. These profiles give a lightweight and solid structure that can uphold weighty loads and endure thorough working circumstances. Whether it's in transport frameworks, mechanical arms, or sequential construction systems, aluminum profiles offer the important steadiness and primary honesty expected for productive computerization.

One more huge utilization of aluminum profiles is in the making of nooks and defensive covers for mechanization gear. These profiles can be effectively gathered and redone to fit explicit aspects and prerequisites. By utilizing aluminum profiles, producers can guarantee the wellbeing and assurance of touchy parts and hardware while keeping up with availability for support and fixes.

Moreover, aluminum profiles are generally utilized in the plan of straight movement frameworks. These profiles act as the spine for straight aides, rails, and actuators, empowering exact and smooth development of mechanization hardware. The lightweight idea of aluminum profiles decreases the general load of the framework, considering quicker speed increase and further developed energy proficiency.

The flexibility of aluminum profiles reaches out to the formation of ergonomic workstations and administrator boards. By using these profiles, producers can plan movable and ergonomic workstations that improve the solace and effectiveness of administrators. Moreover, aluminum profiles can be coordinated with embellishments, for example, screen mounts, console plate, and instrument holders, giving a consistent and coordinated work area.

Case Studies: Real-world Examples of Aluminum Profile Applications

Aluminum profiles are a flexible and broadly involved material in different ventures. They have shown to be fundamental in some certifiable applications, filling in as the spine for various activities. These contextual analyses give important experiences into the tremendous conceivable outcomes and advantages of utilizing aluminum profiles.

One eminent use of aluminum profiles is in the development business. Designers and specialists depend on these profiles to make underlying systems for structures, spans, and other foundation projects. The lightweight idea of aluminum profiles goes with them an optimal decision, as they offer strength and toughness while decreasing the general load of the design. This upgrades the effectiveness of development as well as limits material and work costs.

Another region where aluminum profiles succeed is in the car business. They are broadly utilized in the assembling of vehicle edges and body boards. Aluminum profiles give a lightweight option in contrast to conventional steel, bringing about better eco-friendliness and diminished emanations. Moreover, their erosion safe properties guarantee life span, settling on them an incredible decision for different atmospheric conditions.

The aviation area additionally benefits enormously from the utilization of aluminum profiles. Airplane producers use these profiles widely in the development of wings, fuselages, and inside parts. The high solidarity to-weight proportion of aluminum profiles takes into consideration expanded payload limit and further developed eco-friendliness. Additionally, their protection from outrageous temperatures and protection from weakness pursue them an optimal decision for the requesting states of avionics.

Aluminum profiles likewise track down applications in the electrical business. They are utilized in the development of electrical nooks, heat sinks, and conductive parts. The brilliant warm conductivity of aluminum profiles guarantees effective intensity scattering, making them ideal for electronic gadgets and power transmission frameworks. Furthermore, their non-attractive properties make them reasonable for delicate electrical applications.

Considerations for Choosing Aluminum Profiles in Automation Equipment

With regards to picking aluminum profiles for mechanization gear, there are a few significant contemplations to remember. Aluminum profiles are broadly utilized in computerization hardware for their flexibility, solidness, and lightweight properties. They assume an essential part in guaranteeing the smooth and proficient working of mechanized frameworks.

One of the key contemplations while choosing aluminum profiles is the particular necessities of the computerization hardware. Various sorts of hardware might require various profiles with fluctuating aspects, shapes, and burden bearing limits. It is fundamental to painstakingly investigate the necessities of the gear and pick profiles that can uphold the planned burden and give the essential underlying solidness.

One more significant variable to consider is the quality and dependability of the aluminum profiles. It is vital to choose profiles that are produced utilizing great materials and exact assembling methods. This guarantees that the profiles can endure the afflictions of computerization cycles and proposition long haul solidness. Also, solid profiles add to the general wellbeing and execution of the hardware.

The plan and similarity of the aluminum profiles with different parts of the mechanization gear are likewise huge contemplations. The profiles ought to be viable with connectors, sections, and different extras that are fundamental for the development of the hardware. A very much planned profile framework considers simple get together, dismantling, and change, making it more helpful for support and updates.

Besides, the heaviness of the aluminum profiles is a significant component, particularly in applications where weight decrease is basic. Aluminum profiles are known for their lightweight nature, which adds to energy effectiveness and simplicity of taking care of. By picking lightweight profiles, the general load of the computerization hardware can be limited, bringing about expanded productivity and decreased energy utilization.

Installation and Maintenance of Aluminum Profiles in Automation Equipment

Aluminum profiles assume a critical part in the establishment and upkeep of robotization gear. These flexible parts are generally utilized in different businesses because of their lightweight yet tough properties. From transport frameworks to mechanical arms, aluminum profiles give the essential primary trustworthiness and adaptability expected for computerization processes.

With regards to establishment, one of the vital benefits of aluminum profiles is their usability. These profiles come in different shapes and sizes, considering speedy and basic gathering. The secluded idea of aluminum profiles empowers architects and professionals to plan and develop computerization gear that unequivocally accommodates their particular necessities. With the capacity to handily interface and disengage various profiles, alterations and changes can be made easily.

As far as upkeep, aluminum profiles offer a few advantages. Right off the bat, their erosion opposition guarantees life span and decreases the requirement for incessant substitutions. Furthermore, aluminum profiles are profoundly versatile to outrageous temperatures, making them reasonable for applications in both hot and cold conditions. This toughness guarantees that robotization gear stays functional and proficient for broadened periods.

To advance the presentation of robotization gear, it is critical to choose the suitable aluminum profiles. Factors like burden limit, unbending nature, and similarity with different parts ought to be thought of. By picking profiles that meet the particular prerequisites of the hardware, smooth activity and improved efficiency can be accomplished.

While utilizing aluminum profiles in robotization hardware, guaranteeing appropriate support and standard inspections is significant. This incorporates checking for any indications of wear or harm, like marks or breaks, and quickly addressing them to forestall further issues. Normal oil of moving parts and cleaning of the profiles additionally add to their ideal exhibition.

Challenges and Limitations of Using Aluminum Profiles in Automation Equipment

Aluminum profiles have acquired critical prominence in the computerization business because of their various benefits. Be that as it may, similar to some other material, they additionally accompany their reasonable part of difficulties and limits. Understanding these restrictions is vital for architects and producers to pursue informed choices while integrating aluminum profiles into their mechanization hardware.

One of the essential difficulties of utilizing aluminum profiles in robotization hardware is their moderately low strength contrasted with different materials like steel. While aluminum is lightweight, it may not be appropriate for applications that require high burden bearing limits. Engineers need to painstakingly examine the anxiety necessities of their gear to guarantee that aluminum profiles can endure the normal powers.

One more restriction of aluminum profiles is their powerlessness to consumption. Not at all like hardened steel, which is profoundly impervious to rust and erosion, aluminum profiles can be inclined to oxidation when presented to specific conditions. This can be a critical worry for computerization gear utilized in open air or destructive conditions. To relieve this issue, producers frequently utilize defensive coatings or composites with further developed erosion obstruction.

Accuracy is urgent in computerization hardware, and layered steadiness is a vital element to consider. Aluminum profiles might have a higher coefficient of warm extension contrasted with different materials, which can prompt layered changes with temperature varieties. This can influence the precision and execution of the computerization gear, particularly in applications where tight resistances are required. Engineers need to in like manner represent these warm development qualities and plan the gear.

In spite of the fact that aluminum profiles offer astounding conductivity for electrical applications, they may not be reasonable for conditions with high electromagnetic impedance (EMI). Aluminum isn't generally so compelling as materials like copper in safeguarding against EMI, which can prompt sign obstruction and influence the exhibition of delicate electronic parts. In such cases, specialists might have to consolidate extra safeguarding measures or think about elective materials.

Future Trends and Innovations in Aluminum Profiles for Automation Equipment

Aluminum profiles for mechanization gear have upset the assembling business, empowering productive and exact activities. As innovation keeps on propelling, future patterns and developments in this field are supposed to additional improve computerization processes.

One of the critical patterns in aluminum profiles for computerization hardware is lightweight plan. Producers are continually endeavoring to foster profiles that are lighter yet areas of strength for similarly sturdy. This not just decreases the general load of the hardware yet additionally considers quicker and more coordinated developments, expanding efficiency. The utilization of lightweight aluminum profiles additionally adds to energy proficiency, as less power is expected to work the apparatus.

One more significant pattern is the combination of savvy innovation. Mechanization gear is turning out to be progressively astute, with the capacity to assemble and examine information continuously. Aluminum profiles are being intended to oblige sensors and other savvy parts, empowering gear to self-screen, self-change, and improve execution. This prompts further developed accuracy, decreased free time, and improved wellbeing in modern settings.

Developments in surface medicines are likewise molding the eventual fate of aluminum profiles for robotization gear. Producers are exploring different avenues regarding different coatings and completions to upgrade the profiles' protection from consumption, wear, and tear. By applying progressed coatings, the life expectancy of the profiles can be delayed, bringing about cost investment funds for organizations. Also, these medicines can work on the feel of the hardware, making it all the more outwardly engaging.

Moreover, customization choices are turning out to be progressively significant in the aluminum profile industry. Producers are offering many profiles with various aspects, shapes, and highlights to meet the different necessities of robotization gear. Customization permits organizations to upgrade their apparatus for explicit applications, guaranteeing most extreme productivity and usefulness.

Conclusion

In conclusion, the article highlights the numerous benefits of using aluminum profiles in automation equipment. These profiles offer advantages such as remarkable strength-to-weight ratio, corrosion resistance, versatility, and cost-effectiveness. They have revolutionized the automation industry with their diverse applications and exceptional properties, including unmatched strength, durability, and flexibility. The utilization of aluminum profiles in linear motion systems and ergonomic workstations further enhances the efficiency and functionality of automation equipment. Aluminum profiles have proven to be indispensable in various real-world applications, offering lightweight construction, improved fuel efficiency, and enhanced durability. It is crucial for manufacturers and designers to select the right aluminum profiles based on equipment requirements, quality, design, and weight. The installation and maintenance of aluminum profiles are vital for the smooth operation and longevity of automation systems. While aluminum profiles offer numerous advantages, it is important to consider challenges and limitations, such as strength requirements, corrosion resistance, dimensional stability, and EMI considerations. However, the future of aluminum profiles for automation equipment is promising, with lightweight designs, smart technology integration, advanced surface treatments, and customization options expected to revolutionize the manufacturing industry and drive efficiency and productivity forward.