Modern stream lines assume a critical part in guaranteeing effective and smoothed out tasks in different businesses. One key variable that significantly influences the adequacy of these stream lines is the selection of materials utilized in their development. Lately, aluminum expelled profiles have arisen as a well known and exceptionally viable answer for enhancing modern stream lines.

This article dives into the universe of aluminum expelled profiles and investigates their true capacity in improving the presentation of modern stream lines. By understanding the remarkable attributes and benefits of these profiles, organizations can go with informed choices to expand their functional proficiency.

The article starts by giving a thorough outline of aluminum expelled profiles, revealing insight into their assembling cycle and the properties that make them ideal for modern applications. It then, at that point, dives into the different manners by which these profiles can be used to advance stream lines, examining the key plan contemplations that should be considered.

Moreover, the article investigates the execution and upkeep parts of utilizing aluminum expelled profiles in stream lines, giving bits of knowledge into best practices and systems for guaranteeing long haul achievement. Toward the finish of this article, perusers will have a strong comprehension of how aluminum expelled profiles can reform their modern stream lines, prompting expanded efficiency, cost reserve funds, and in general functional greatness.

Understanding Aluminum Extruded Profiles

Aluminum expelled profiles assume a urgent part in different ventures, offering a great many applications and advantages. Understanding the complexities of these profiles is fundamental for organizations and people the same.

Aluminum profiles are adaptable and lightweight, making them profoundly pursued in businesses like development, car, aviation, and hardware. These profiles offer gigantic strength and sturdiness, pursuing them an incredible decision for primary applications. Moreover, their erosion safe properties make them ideal for open air and cruel conditions.

One of the critical benefits of aluminum profiles is their adaptability in plan. They can be specially designed into different shapes and sizes to meet explicit prerequisites. This adaptability considers vast conceivable outcomes in design and modern applications. From window edges and drape walls to warm sinks and electrical fenced in areas, aluminum profiles can be custom-made to fit any venture.

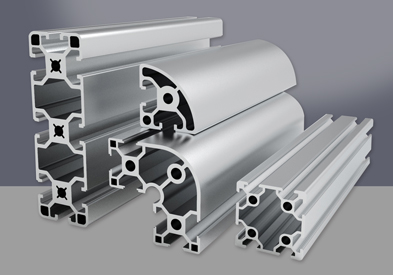

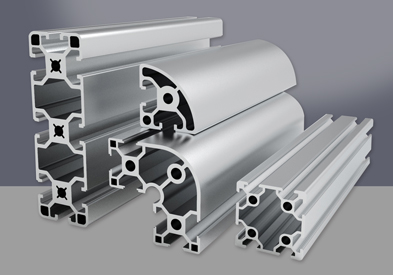

The assembling system of aluminum expelled profiles is similarly noteworthy. It includes pushing warmed aluminum billets through a kick the bucket to make the ideal shape. This cycle gives the profiles their special properties, including their solidarity and exact aspects. Current expulsion methods guarantee excellent profiles with predictable cross-sectional shapes, making them appropriate for perplexing plans.

With regards to maintainability, aluminum profiles are intrinsically eco-accommodating. Aluminum is a recyclable material, and the expulsion cycle consumes less energy contrasted with other assembling strategies. This goes with aluminum profiles a manageable decision for the people who focus on natural cognizance.

To completely use the advantages of aluminum profiles, it means a lot to work with a trustworthy provider. They can give master direction on picking the right compound, profile plan, and surface completion to suit explicit applications. Furthermore, working with a the provider significance of value control guarantees that the profiles satisfy industry guidelines and guidelines.

Optimizing Industrial Flow Lines with Aluminum Extruded Profiles

Streamlining modern stream lines is vital for improving effectiveness and efficiency in assembling processes. One viable method for accomplishing this enhancement is by using aluminum expelled profiles. These profiles offer various benefits that can significantly add to smoothing out tasks.

Aluminum profiles are eminent for their lightweight yet tough nature, settling on them an optimal decision for modern applications. Their high solidarity to-weight proportion guarantees strength while limiting by and large weight, taking into account simpler dealing with and establishment. This lightweight trademark likewise lessens energy utilization during transportation, bringing about cost investment funds and a more practical methodology.

One more critical benefit of aluminum profiles is their flexibility in plan. They can be expelled into different shapes and sizes, empowering customization to meet explicit stream line necessities. This adaptability works with the formation of productive and ergonomic workstations, guaranteeing consistent joining of gear and hardware. By upgrading the stream line format, efficiency can be improved, and bottlenecks can be limited or disposed of.

Notwithstanding their plan flexibility, aluminum profiles offer great erosion obstruction. This is especially significant in modern settings where openness to dampness, synthetics, and other brutal components is normal. By utilizing consumption safe aluminum profiles, the life expectancy of stream line designs can be expanded, decreasing upkeep expenses and free time.

The use of aluminum profiles likewise adds to a cleaner and more secure workplace. Not at all like different materials, aluminum is non-flammable and doesn't deliver poisonous exhaust when presented to high temperatures. This guarantees the wellbeing of representatives and limits the gamble of fire perils.

Moreover, the expulsion interaction used to make aluminum profiles takes into account exact resiliences, guaranteeing precise and steady aspects. This accuracy is essential for consistent joining of parts inside the stream line, keeping away from any disturbances or failures in the assembling system.

Design Considerations for Flow Line Optimization

Stream line enhancement is a basic part of any assembling interaction. It includes investigating and working on the proficiency of the creation line to augment yield and limit costs. One key element that adds to stream line advancement is the plan of aluminum profiles utilized in the creation cycle.

Aluminum profiles assume a critical part in guaranteeing smooth and consistent stream all through the creation line. These profiles are lightweight, sturdy, and proposition great adaptability in plan. While considering stream line improvement, it is fundamental for consider a few plan contemplations.

Most importantly, the elements of the aluminum profiles should be painstakingly picked. The size and state of the profiles ought to be improved to guarantee productive material stream. By choosing the right aspects, producers can limit squander and boost the use of assets.

One more pivotal thought is the joining of frill and connectors. These parts assume an imperative part in associating various segments of the stream line and guaranteeing a consistent progress. The plan of these extras ought to be painstakingly wanted to guarantee simple establishment, negligible personal time, and most extreme efficiency.

Furthermore, the material utilized for the aluminum profiles ought to be painstakingly chosen. Aluminum is a famous decision because of its lightweight nature and superb solidarity to-weight proportion. In any case, there are various grades and amalgams accessible, each with its one of a kind properties. Makers should pick the right material in light of the particular necessities of their creation cycle.

Besides, the surface completion of the aluminum profiles is another basic thought. The surface completion influences the contact between the profiles and the materials being shipped. A smooth surface completion can diminish erosion, taking into consideration smoother material stream and limiting the gamble of harm or tainting.

Implementation and Maintenance of Aluminum Extruded Profiles in Flow Lines

Execution and support of aluminum expelled profiles in stream lines assume a vital part in different enterprises. These profiles, produced using excellent aluminum, offer various advantages like strength, sturdiness, and adaptability. They are generally utilized in the auto, aviation, development, and assembling areas, among others.

One of the critical benefits of aluminum profiles is their lightweight nature, which causes them ideal for applications that to require diminished load without settling for less on strength. This makes them exceptionally reasonable for use in stream lines, where the development of materials and items is fundamental. Aluminum profiles can be effortlessly coordinated into existing stream line frameworks, giving a consistent and productive material taking care of interaction.

The execution of aluminum expelled profiles in stream lines requires cautious preparation and thought. It, first and foremost, is vital to evaluate the particular prerequisites of the stream line and recognize the proper profile plan. The aspects, weight-bearing limit, and underlying uprightness of the profiles should line up with the expected application. This guarantees that the stream line works without a hitch and proficiently, limiting the gamble of personal time or disturbances.

When the profiles have been chosen, appropriate establishment and upkeep are fundamental for ideal execution. The profiles ought to be safely attached to forestall any development or misalignment during activity. Customary reviews ought to be led to recognize any indications of wear, consumption, or harm. Any issues ought to be quickly addressed to forestall further decay and guarantee the life span of the stream line framework.

To keep up with the honesty of the stream line, it is critical to follow suggested support rehearses. This incorporates customary cleaning of the profiles to eliminate any trash or foreign substances that might block their exhibition. Oil of moving parts is additionally important to limit erosion and guarantee smooth activity. Moreover, intermittent adjustment and arrangement checks ought to be directed to keep up with the exactness and accuracy of the stream line.

Conclusion

In conclusion, aluminum extruded profiles offer a wide range of possibilities for various industries. Their versatility, strength, and eco-friendliness make them a preferred choice for architects, engineers, and manufacturers. By working with a trusted supplier and utilizing their expertise, businesses and individuals can benefit from the numerous advantages that aluminum profiles have to offer.

Optimizing industrial flow lines with aluminum extruded profiles also offers numerous benefits. Their lightweight nature, design versatility, corrosion resistance, and safety features make them an ideal choice for enhancing productivity and efficiency. By utilizing these profiles, manufacturers can achieve seamless integration, reduce maintenance costs, and create a more sustainable and ergonomic work environment. Embracing aluminum profiles is a step towards optimizing industrial flow lines and staying ahead in the competitive manufacturing industry.

When optimizing flow lines, careful consideration must be given to the design of aluminum profiles. The dimensions, integration of accessories, material selection, and surface finish all play a crucial role in ensuring efficient and cost-effective production processes. By paying attention to these design considerations, manufacturers can achieve flow line optimization, leading to increased productivity, reduced costs, and improved overall efficiency. It is crucial to work with experienced professionals who understand the intricacies of flow line optimization and can provide tailored solutions to meet specific manufacturing needs.

The implementation and maintenance of aluminum extruded profiles in flow lines offer significant advantages in terms of efficiency, durability, and versatility. These profiles, when properly selected and installed, enhance the overall performance of flow line systems. Regular maintenance and adherence to recommended practices ensure the longevity and reliability of the profiles, contributing to seamless material handling processes. With their lightweight yet robust nature, aluminum profiles continue to be a preferred choice in various industries, revolutionizing the way flow lines operate.