Aluminum profile get together assumes a urgent part in the assembling business, and understanding the procedures included can essentially further develop creation proficiency. Whether you are new to aluminum profile gathering or hoping to improve your current cycles, this article will furnish you with significant bits of knowledge and best practices. In the principal segment, we will dive into the basics of aluminum profile gathering, investigating its significance and the different parts included. Then, we will talk about the fundamental stages to plan for fruitful gathering, including choosing the right instruments and materials, as well as guaranteeing legitimate security measures. Continuing on, we will investigate the methods that can smooth out the get together cycle, upgrade work process, and limit mistakes. At long last, we will feature probably the prescribed procedures in aluminum profile gathering, drawing from industry specialists and contextual analyses. Toward the finish of this article, you will have an exhaustive comprehension of the procedures and systems to accomplish more proficient creation in aluminum profile gathering.

Understanding Aluminum Profile Assembly

Aluminum profiles are broadly utilized in different businesses because of their lightweight, toughness, and adaptability. These profiles are fundamental parts in the development of designs, hardware, and even furnishings. Notwithstanding, understanding the gathering system of aluminum profiles is essential to guarantee their appropriate usefulness and life span.

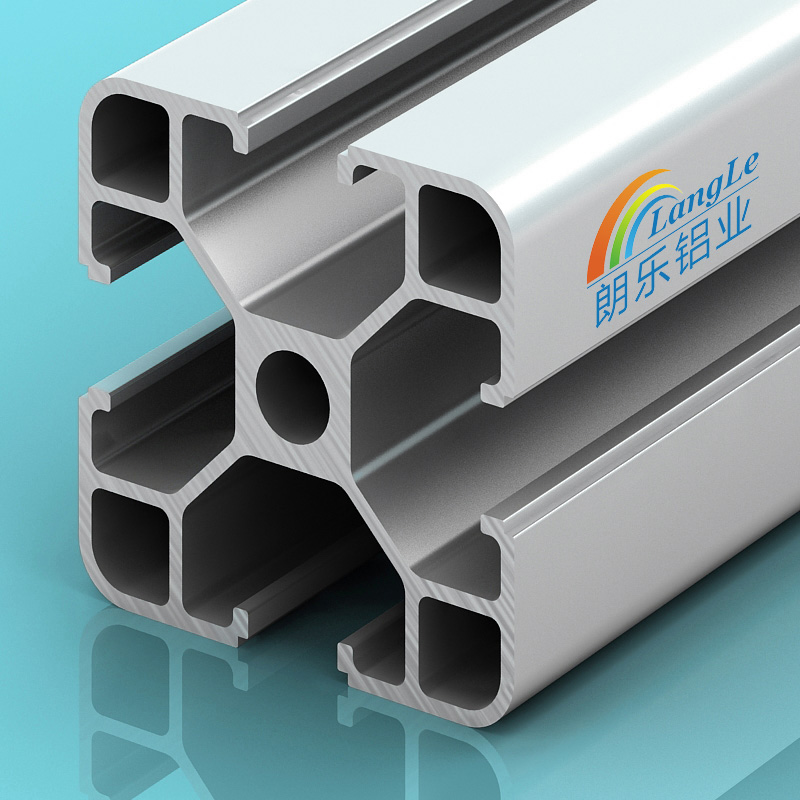

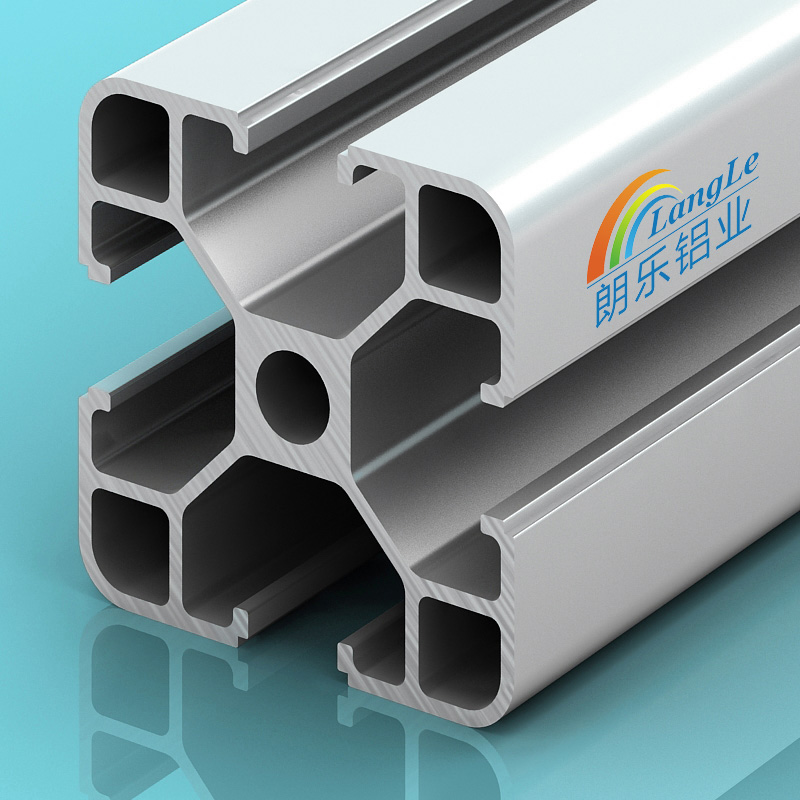

The most important phase in aluminum profile get together is the determination of the fitting profiles for the particular application. Aluminum profiles come in different shapes and sizes, each intended for explicit purposes. It is fundamental to consider factors like burden bearing limit, style, and underlying necessities while picking the profiles. Furthermore, the similarity of various profiles ought to be inspected to guarantee a consistent gathering.

When the profiles are chosen, the gathering system starts with slicing the profiles to the ideal lengths. This step expects accuracy to guarantee precise estimations and a legitimate fit. Specific cutting apparatuses, for example, miter saws or accuracy saws, are utilized to accomplish perfect and exact cuts.

In the wake of cutting, the subsequent stage is to set up the profiles for gathering. This includes deburring the slice edges to eliminate any sharp or harsh edges. Deburring not just improves the tasteful allure of the gathering yet additionally kills potential security perils. Different deburring techniques, like documenting, sanding, or utilizing deburring apparatuses, can be utilized relying upon the intricacy of the profiles.

The gathering of aluminum profiles normally includes interfacing different pieces together to make a firm construction. Different strategies can be utilized for gathering, including mechanical securing, welding, or cement holding. Mechanical securing, like utilizing screws, fasteners, or sections, is a famous decision because of its straightforwardness and simplicity of dismantling whenever required. Welding, then again, gives a more long-lasting and hearty association yet requires specific hardware and mastery.

During the gathering system, guaranteeing appropriate arrangement and parity of the profiles is significant. This can be accomplished by utilizing arrangement instruments, like squares or laser arrangement gadgets. Legitimate arrangement not just upgrades the underlying respectability of the gathering yet additionally works on its tasteful allure.

At last, after the gathering is finished, it is vital for lead intensive quality checks to guarantee the uprightness of the construction. This incorporates examining the associations for any indications of detachment or deformities and confirming the general solidness of the get together.

Preparing for Aluminum Profile Assembly

Aluminum profiles have become progressively well known in different businesses because of their lightweight, sturdy, and flexible nature. They are generally utilized in development, car, and assembling areas for their uncommon solidarity to-weight proportion and erosion obstruction. In any case, to guarantee an effective aluminum profile gathering, legitimate readiness is essential.

The most important phase in getting ready for aluminum profile gathering is to clean the profiles completely. Any soil, residue, or oil on a superficial level can prevent the viability of glues or welding. Utilizing a gentle cleanser and water, delicately clean the profiles to eliminate any pollutants. In the wake of cleaning, guarantee the profiles are totally dry prior to continuing to the following stage.

Then, it is fundamental to assess the aluminum profiles for any imperfections or harms. Check for any marks, scratches, or disfigurements that might influence the gathering system. On the off chance that any issues are found, it is prescribed to supplant the harmed profiles to guarantee a consistent gathering.

When the profiles are perfect and liberated from deserts, the time has come to set up the essential apparatuses and hardware. Contingent upon the gathering technique picked, various apparatuses might be required. For glue holding, guarantee you have the proper cement and instrument. For welding, guarantee you have a reasonable welding machine and defensive stuff. Legitimate readiness of the instruments guarantees a smooth get together interaction and lessens the gamble of mistakes or deferrals.

Prior to beginning the gathering, it is critical to precisely plan and measure the format. Take exact estimations of the profiles and imprint the situations for boring, cutting, or joining. This step guarantees that the get together is exact and lines up with the ideal plan or construction.

During the gathering system, it is fundamental to deal with the aluminum profiles with care to keep away from any superfluous harm or scratches. Utilize legitimate lifting strategies and defensive covers to forestall any surface defacing. Moreover, guarantee that all clasp, cements, or welding methods utilized are reasonable for aluminum profiles to guarantee major areas of strength for a strong gathering.

Techniques for Efficient Aluminum Profile Assembly

Aluminum profiles are generally utilized in different businesses because of their flexibility and solidness. With regards to productive gathering of aluminum profiles, there are a few methods that can be utilized to guarantee a consistent and solid development.

One significant strategy is appropriate estimation and cutting of the profiles. Exact estimations are essential for accomplishing an exact fit during gathering. Utilizing a top notch estimating device and a sharp cutting instrument, for example, a miter saw, can assist with accomplishing spotless and exact cuts. This guarantees that the profiles fit together consistently, bringing about areas of strength for a steady construction.

One more strategy for effective aluminum profile gathering is the utilization of reasonable connectors and latches. Connectors assume a fundamental part in joining various segments of the profiles together. They should areas of strength for be sturdy to endure the weight and stress put on the gathering. Picking the right connectors that are explicitly intended for aluminum profiles is fundamental for guaranteeing a protected and enduring association.

Furthermore, appropriate arrangement of the profiles before get together is significant for proficient gathering. This incorporates cleaning the profiles to eliminate any soil, residue, or trash that might slow down the gathering system. It is additionally essential to guarantee that the profiles are liberated from any deformities or harms that might influence their underlying uprightness. Ordinary review and upkeep of the profiles can help recognize and resolve any issues before get together.

Besides, utilizing proper devices and gear can enormously improve the proficiency of aluminum profile gathering. Power apparatuses, like drills and screwdrivers, can accelerate the gathering system and guarantee exact and get attaching. Moreover, utilizing clasps or dances can hold the profiles set up during get together, taking into consideration exact arrangement and simpler establishment.

Best Practices for Aluminum Profile Assembly

Aluminum profile gathering is a critical stage in different businesses, going from development to auto. To guarantee a consistent and durable design, following prescribed procedures is fundamental.

First and foremost, choosing the right aluminum profiles is vital. These profiles come in different shapes, estimates, and compounds, each taking care of explicit applications. Understanding the prerequisites of the undertaking and picking profiles that address those issues is fundamental for an effective gathering process.

Then, appropriate taking care of and stockpiling of the aluminum profiles is urgent. They ought to be put away in a perfect and dry climate to forestall any consumption or harm. It is additionally vital to deal with the profiles with care, trying not to any unpleasant handle that could bring about imprints or scratches, undermining their trustworthiness.

With regards to cutting and machining the profiles, accuracy is principal. Utilizing exact estimations and top notch cutting apparatuses will guarantee clean cuts and exact points. Also, utilizing proper machining procedures, for example, processing or boring can additionally upgrade the gathering system.

Besides, joining the aluminum profiles really is urgent for their primary respectability. There are different techniques for joining, including welding, darting, or utilizing glues. Every technique enjoys its own benefits and contemplations, and picking the most reasonable one for the particular application is indispensable. Legitimate preparation and skill in these joining procedures are important to guarantee serious areas of strength for a solid gathering.

To upgrade the life span and execution of the gathered aluminum profiles, it are frequently applied to complete medicines. These medicines can incorporate anodizing, powder covering, or painting, contingent upon the ideal tasteful and useful prerequisites. These completions safeguard the profiles from erosion as well as give an outwardly engaging appearance.

Conclusion

In conclusion, understanding the assembly process of aluminum profiles is crucial for their successful integration into various applications. By carefully selecting the appropriate profiles, performing accurate cuts, and employing proper assembly techniques, the functionality and longevity of aluminum profile assemblies can be maximized. Proper cleaning, inspection, tool preparation, accurate measurement, and careful handling are all essential aspects of the preparation process. By following these steps diligently, you can ensure a seamless assembly that maximizes the benefits of aluminum profiles in various applications. Efficient aluminum profile assembly requires proper measurement and cutting, the use of suitable connectors and fasteners, adequate preparation, and the utilization of appropriate tools and equipment. By employing these techniques, professionals can ensure a smooth and hassle-free assembly process, resulting in high-quality and durable structures. Following best practices for aluminum profile assembly is crucial for achieving a successful outcome. From selecting the right profiles to employing proper handling, cutting, joining, and finishing techniques, every step plays a significant role in the durability and functionality of the final assembly. By adhering to these practices, industries can confidently rely on aluminum profiles for their structural needs.