Cleanrooms are basic conditions that require severe command over defilement levels. To guarantee the best guidelines, using the right materials and development methods is fundamental. One such material that has shown to be profoundly powerful in improving cleanroom quality is aluminum profiles.

In this article, we will dig into the universe of cleanrooms and investigate the different parts of utilizing aluminum profiles for their development. We will begin by understanding the particular necessities of cleanrooms and how they vary from standard conditions. This understanding will give a strong groundwork to valuing the advantages that aluminum profiles bring to cleanrooms.

We will then, at that point, investigate the various benefits of utilizing aluminum profiles in cleanrooms. From their excellent strength and solidness to their protection from consumption and tainting, aluminum profiles offer a scope of highlights that make them ideal for cleanroom applications.

Besides, we will analyze the different utilizations of aluminum profiles in cleanrooms. Whether it is for segments, racking frameworks, or hardware outlines, aluminum profiles give adaptable arrangements that can be custom fitted to meet explicit cleanroom needs.

While aluminum profiles offer various advantages, there are additionally key contemplations that should be considered while involving them in cleanrooms. We will talk about these contemplations, including elements like surface completions, joint plans, and similarity with other cleanroom materials.

To build up the viability of aluminum profiles in cleanrooms, we will introduce contextual analyses displaying fruitful executions. These genuine models will feature the positive effect that aluminum profiles have had on cleanroom quality and execution.

At last, we will finish up by seeing future patterns and developments in aluminum profiles for cleanrooms. As innovation and industry necessities keep on developing, it is vital to remain refreshed on the most recent headways in cleanroom development materials.

Toward the finish of this article, perusers will have a thorough comprehension of the job that aluminum profiles play in improving cleanroom quality. Whether you are associated with cleanroom plan, development, or upkeep, this article will give important bits of knowledge into boosting cleanroom execution and guaranteeing the most significant levels of defilement control.

Understanding Cleanroom Requirements

Cleanrooms are particular conditions that are intended to keep up with incredibly low degrees of particulate defilement. These controlled conditions are urgent in businesses like drugs, biotechnology, hardware, and aviation, where even the littlest particles can negatively affect the assembling processes and the end results. To guarantee the viability of cleanrooms, severe prerequisites are set up to manage different perspectives, including air quality, temperature, mugginess, and tidiness.

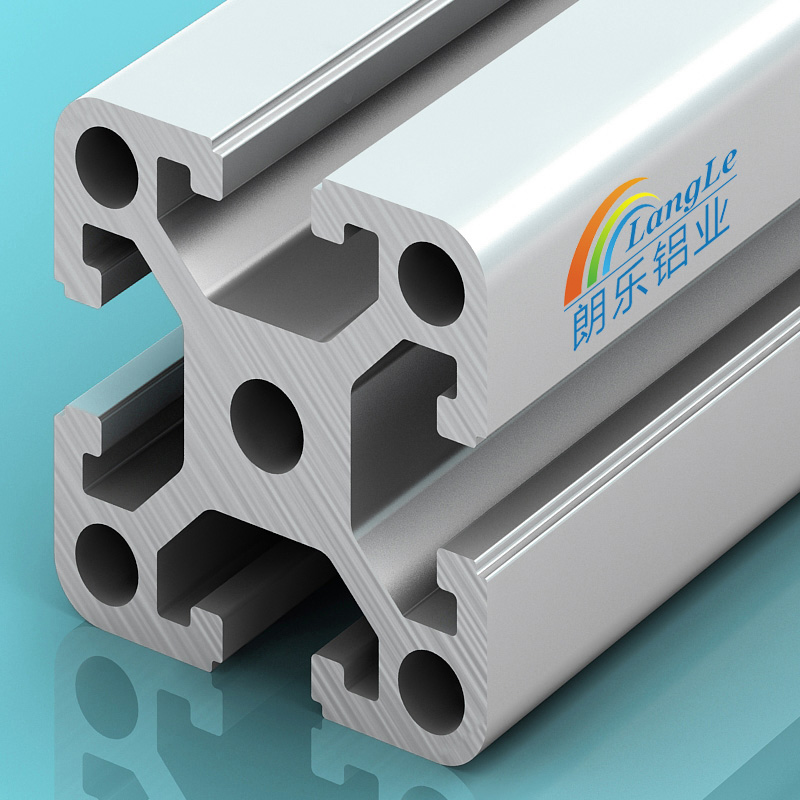

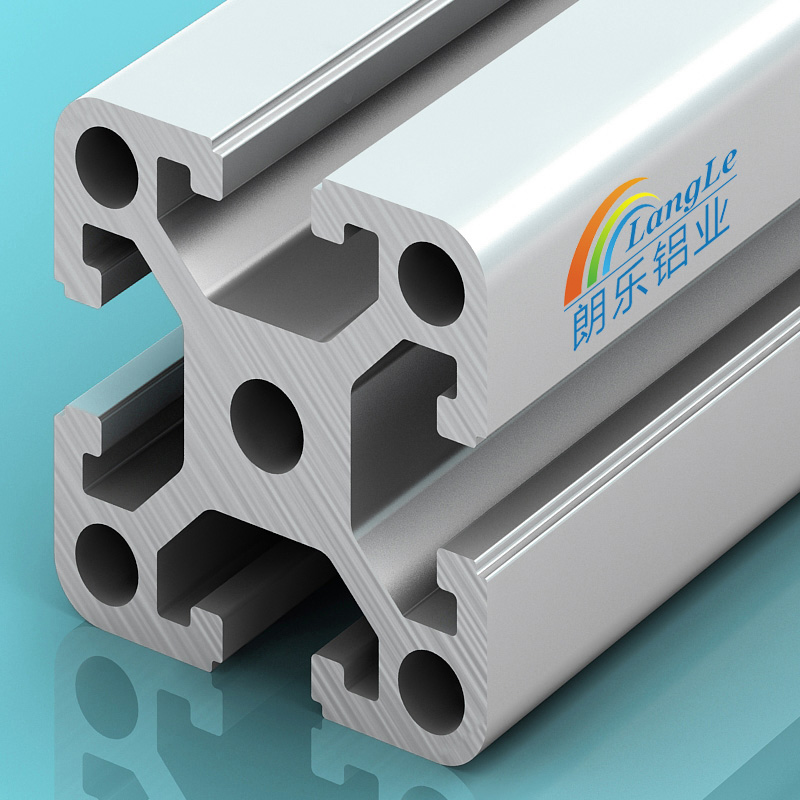

One of the critical parts in cleanroom development is the utilization of aluminum profiles. These profiles are lightweight, sturdy, and have phenomenal erosion obstruction properties, making them ideal for making the system and designs inside cleanrooms. Aluminum profiles are in many cases used to develop walls, roofs, and floor upholds, giving a strong and stable starting point for the cleanroom climate.

With regards to cleanroom prerequisites, air quality is of most extreme significance. The air in a cleanroom should be persistently sifted and circled to eliminate particles and foreign substances. The utilization of high-proficiency particulate air (HEPA) channels is normal in cleanrooms to accomplish the ideal air quality. These channels are equipped for catching particles as little as 0.3 micrometers with a proficiency of 99.97%. Moreover, cleanrooms frequently utilize laminar wind current frameworks, where separated air is presented in a uniform and controlled way to limit choppiness and forestall the collection of impurities.

Temperature and stickiness control is one more basic part of cleanroom necessities. Cleanrooms are ordinarily kept up with at a somewhat certain strain contrasted with the encompassing regions to forestall the penetration of unfiltered air. This positive tension likewise assists with controlling the temperature and mugginess levels inside the cleanroom. Temperature and mugginess checking frameworks are introduced to guarantee that the circumstances inside the cleanroom stay inside the predefined range consistently.

Neatness is a definitive objective of any cleanroom. Customary cleaning and upkeep techniques are executed to eliminate any possible wellsprings of pollution. Particular cleaning specialists and sanitizers are utilized to clean surfaces, gear, and instruments inside the cleanroom. Pollution control conventions, for example, the utilization of cleanroom articles of clothing, gloves, and shoe covers, are completely upheld to limit the presentation of particles from faculty.

Benefits of Aluminum Profiles in Cleanrooms

Aluminum profiles are turning out to be progressively well known in the development and plan of cleanrooms, and for good explanation. These adaptable structure materials offer various advantages that go with them an optimal decision for cleanroom applications.

One of the vital benefits of utilizing aluminum profiles in cleanrooms is their extraordinary strength. Cleanrooms require materials that can endure the thorough requests of keeping a controlled climate. Aluminum profiles are known for their solidarity and strength, making them exceptionally appropriate for cleanroom development. They can endure weighty loads and oppose consumption, guaranteeing the life span and honesty of the cleanroom structure.

Notwithstanding their sturdiness, aluminum profiles offer astounding adaptability in cleanroom plan. Cleanrooms frequently require explicit arrangements and formats to oblige different cycles and hardware. Aluminum profiles can be handily altered and created to meet the remarkable requirements of each cleanroom project. They can be cut, molded, and collected to make particular cleanroom structures, taking into account simple alteration and development when required.

One more huge advantage of utilizing aluminum profiles in cleanrooms is their lightweight nature. Contrasted with customary development materials, for example, steel, aluminum profiles are a lot lighter, making them more straightforward to deal with and introduce. This diminishes work costs as well as limits the general weight load on the cleanroom structure. Furthermore, the lightweight idea of aluminum profiles considers greater adaptability in cleanroom configuration, empowering the formation of mind boggling and complex designs.

Aluminum profiles additionally offer brilliant warm conductivity, which is essential in cleanroom conditions. Cleanrooms require exact temperature control to keep up with the ideal circumstances for delicate cycles. Aluminum profiles productively move heat, taking into account successful temperature guideline inside the cleanroom. This assists with guaranteeing predictable and stable working circumstances, limiting the gamble of pollution and guaranteeing the ideal exhibition of cleanroom hardware.

Moreover, aluminum profiles are exceptionally impervious to dampness and mugginess, making them ideal for cleanroom applications. Cleanrooms need to keep up with low degrees of mugginess to forestall the development of microbial impurities. Aluminum profiles don't retain dampness, diminishing the gamble of shape and microorganisms arrangement. This settles on them an astounding decision for cleanroom development, where keeping up with severe neatness and cleanliness principles is vital.

Applications of Aluminum Profiles in Cleanrooms

Aluminum profiles assume a significant part in the development and plan of cleanrooms. These particular conditions require severe command over air quality, particulate pollution, and temperature. With their novel properties, aluminum profiles offer various applications and advantages inside cleanroom offices.

One of the essential purposes of aluminum profiles in cleanrooms is for outlining frameworks. Aluminum's lightweight yet hearty nature makes it an optimal material for developing designs that should be strong and stable. These profiles are regularly used to make walls, segments, and roof lattices, giving a strong system to the cleanroom's general design.

In addition, the adaptability of aluminum profiles considers the simple coordination of different parts and frill expected in cleanroom settings. These profiles can be modified and intended to oblige electrical wiring, funneling frameworks, and air filtration units. By integrating these components into the aluminum profiles, cleanroom creators can guarantee a smoothed out and proficient format, upgrading the space accessible.

One more fundamental use of aluminum profiles in cleanrooms is the production of entryways and windows. These profiles give a safe and water/air proof seal, keeping the entrance of toxins from outside the controlled climate. The lightweight idea of aluminum likewise takes into consideration simple activity and support of these openings, guaranteeing smooth access for staff and gear without compromising tidiness.

Besides, aluminum profiles are pivotal for the establishment of cleanroom gear and installations. From racking units to workstations, aluminum profiles give serious areas of strength for a solid emotionally supportive network. These profiles can be handily changed and reconfigured according to the particular necessities of the cleanroom, taking into account adaptability and versatility.

Key Considerations for Using Aluminum Profiles in Cleanrooms

With regards to establishing a perfect and sterile climate, utilizing aluminum profiles can be a key thought. These profiles offer a scope of advantages that make them appropriate for use in cleanrooms. One of the principal benefits of aluminum profiles is their capacity to oppose consumption. This is particularly significant in cleanrooms where the presence of dampness and synthetic compounds can be unfavorable to different materials. Aluminum profiles likewise have a high solidarity to-weight proportion, making them sturdy and dependable. This is significant in cleanrooms where gear and apparatuses need to endure consistent use and likely effects.

Another significant thought while utilizing aluminum profiles in cleanrooms is their capacity to be effectively cleaned and disinfected. Cleanrooms require standard cleaning and sterilization to keep a clean climate, and aluminum profiles improve on this interaction. They can be handily cleaned down and sanitized without the gamble of harming the material. This recoveries time as well as guarantees that the cleanroom stays liberated from foreign substances.

Notwithstanding their down to earth benefits, aluminum profiles offer plan adaptability. They can be effectively redone and manufactured to meet explicit cleanroom prerequisites. This takes into consideration consistent joining with other cleanroom parts, like walls, roofs, and installations. The flexibility of aluminum profiles likewise implies that they can be utilized in an assortment of cleanroom applications, from drug and biotech offices to hardware fabricating.

While utilizing aluminum profiles in cleanrooms, it is essential to consider the particular prerequisites of the cleanroom climate. Factors like temperature, moistness, and air quality assume a pivotal part in deciding the reasonableness of aluminum profiles. Also, it is critical to guarantee that the profiles fulfill industry guidelines and guidelines for cleanroom development.

Case Studies: Successful Implementation of Aluminum Profiles in Cleanrooms

Aluminum profiles have demonstrated to be a unique advantage in cleanroom conditions. Contextual analyses have shown effective execution of these profiles, bringing about superior proficiency and improved tidiness.

One prominent contextual investigation included a drug organization that looked to update their cleanroom offices. They perceived the requirement for a dependable and solid arrangement that would meet the rigid tidiness prerequisites of the business. After cautious exploration and assessment, they selected the utilization of aluminum profiles.

The execution of aluminum profiles in their cleanrooms achieved a few advantages. First and foremost, the profiles offered outstanding strength and sturdiness, guaranteeing durable execution of the cleanroom structure. This was especially significant as the organization intended to keep a sterile climate that would endure incessant cleaning and cleansing cycles.

Also, the utilization of aluminum profiles took into account simple customization and adaptability. The organization had the option to plan and build cleanroom parcels and fenced in areas that impeccably accommodated their particular necessities. The profiles could be effortlessly cut, molded, and gathered, empowering the formation of secluded cleanroom frameworks that could be adjusted to evolving necessities.

Moreover, the aluminum profiles ended up being exceptionally impervious to erosion and pollution. This was pivotal in keeping up with the neatness of the cleanroom climate. The profiles had the option to endure openness to different cleaning specialists and synthetics without undermining their underlying trustworthiness.

Another fruitful contextual investigation included a semiconductor producing organization. They confronted difficulties in establishing a controlled climate for their exceptionally touchy assembling processes. By integrating aluminum profiles into their cleanrooms, they had the option to accomplish an elevated degree of accuracy and control.

The lightweight idea of the aluminum profiles took into account simple establishment and reconfiguration of cleanroom parts. This empowered the semiconductor organization to improve their work process and expand the use of their cleanroom space. The profiles likewise worked with the combination of cutting edge innovation, for example, air filtration frameworks and observing hardware, further upgrading the productivity and adequacy of their cleanroom tasks.

Future Trends and Innovations in Aluminum Profiles for Cleanrooms

In the steadily developing universe of cleanrooms, aluminum profiles have arisen as a critical part in guaranteeing proficient and clean conditions. These profiles, produced using great aluminum combinations, offer a huge number of advantages that add to what's in store patterns and developments in cleanroom innovation.

One of the main benefits of using aluminum profiles in cleanrooms is their excellent strength and solidness. These profiles can endure weighty loads and keep up with their primary respectability, making them ideal for supporting different gear and apparatuses inside the cleanroom. Furthermore, their protection from consumption and rust guarantees a long life expectancy, lessening the requirement for incessant substitutions and limiting personal time.

Another key angle driving what's in store patterns in aluminum profiles for cleanrooms is their flexibility and simplicity of customization. These profiles can be handily machined and created to meet the particular necessities of various cleanroom applications. Whether it's planning allotments, retires, or even coordinated frameworks, aluminum profiles give adaptability in making customized arrangements that boost space usage and upgrade work process proficiency.

Advancement is additionally driving the improvement of aluminum profiles for cleanrooms. Progressions in assembling strategies and materials are continually pushing the limits of what can be accomplished with these profiles. For example, the presentation of expulsion innovations takes into consideration the production of mind boggling profiles with complex plans and exact resistances. This empowers cleanroom originators to integrate extraordinary highlights and functionalities into their activities, further upgrading the general exhibition and style of the cleanroom climate.

Moreover, the lightweight idea of aluminum profiles is changing cleanroom development and establishment processes. Contrasted with conventional materials, for example, steel, aluminum profiles are essentially lighter, making them simpler to deal with and control during gathering. This saves time and exertion as well as decreases the general development costs. Also, the lightweight idea of aluminum profiles limits the stress on supporting designs, guaranteeing the solidness and long haul uprightness of the cleanroom office.

Conclusion

In conclusion, understanding cleanroom requirements is essential for industries that rely on controlled environments to ensure product quality and safety. Aluminum profiles play a crucial role in cleanroom construction, providing a robust framework for the cleanroom environment. By adhering to strict requirements for air quality, temperature, humidity, and cleanliness, cleanrooms can effectively minimize the risks associated with particulate contamination and maintain a controlled and sterile environment for critical manufacturing processes. The benefits of using aluminum profiles in cleanrooms are numerous. Their durability, versatility, lightweight nature, thermal conductivity, and resistance to moisture make them an ideal choice for cleanroom construction. With their exceptional properties, aluminum profiles not only ensure the structural integrity of cleanrooms but also contribute to the overall efficiency and effectiveness of cleanroom operations. Aluminum profiles are indispensable in the construction and functionality of cleanrooms. Their lightweight, durable, and customizable nature makes them an ideal choice for framing systems, doors, windows, and equipment installation. By incorporating aluminum profiles into cleanroom designs, facilities can achieve optimal efficiency, control, and cleanliness necessary for a wide range of industries, including pharmaceuticals, electronics, and healthcare. The use of aluminum profiles in cleanrooms offers numerous benefits. Their resistance to corrosion, durability, ease of cleaning, and design flexibility make them an ideal choice for creating and maintaining a clean and sterile environment. The successful implementation of aluminum profiles in cleanrooms has revolutionized the industry, offering exceptional strength, customization options, and resistance to corrosion. Aluminum profiles have become a go-to solution for companies aiming to create and maintain cleanroom environments that meet the highest standards of cleanliness and efficiency. The future of cleanrooms lies in the continuous advancements and innovations in aluminum profiles, which offer exceptional strength, versatility, and customization options. As the demand for clean and sterile environments continues to grow, the use of aluminum profiles will undoubtedly play a crucial role in shaping the future trends and innovations in cleanroom technology.