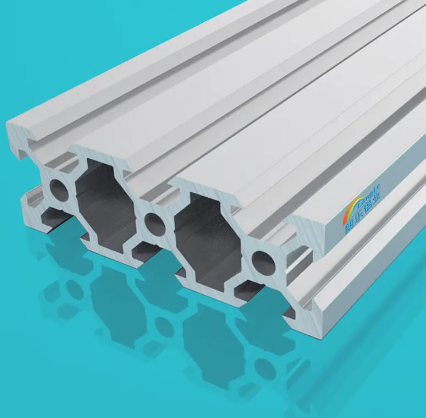

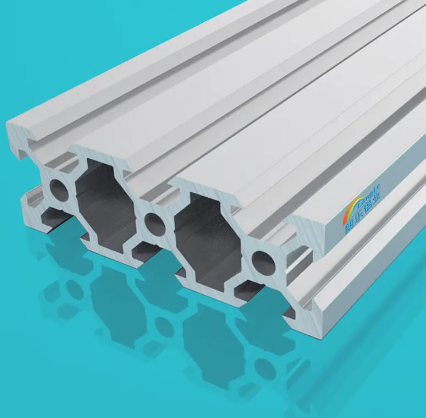

Aluminum profiles are widely used in various industries due to their lightweight, durability, and versatility. From construction to automotive, these profiles are essential for creating strong, corrosion-resistant structures. However, the efficiency and functionality of aluminum profiles depend significantly on the aluminum profile accessories used. Choosing the right accessories, such as connectors, fittings, and other components, is crucial to ensure the stability and longevity of the overall structure. This article provides a comprehensive guide on how to choose the right aluminum profile accessories, focusing on key factors such as material, compatibility, and application.

Selecting the appropriate aluminum profile fitting can be a daunting task, especially with the variety of options available in the market. Whether you are working on an industrial project or a smaller-scale application, understanding the different types of aluminum extrusion profile accessories is essential for making an informed decision. This guide will also highlight the importance of working with a reputable aluminum profile accessories manufacturer to ensure product quality and reliability.

Factors to Consider When Choosing Aluminum Profile Accessories

1. Material Composition

The material composition of aluminum profile accessories plays a significant role in determining their durability and performance. Common materials used include aluminum, stainless steel, and plastic. Aluminum is the most popular choice due to its lightweight, corrosion resistance, and ease of processing. Stainless steel, on the other hand, offers superior strength and is ideal for heavy-duty applications. Plastic accessories are more affordable but may lack the durability required for industrial use.

When selecting aluminum profile connectors, it is essential to consider the environment in which they will be used. For example, in environments exposed to moisture or chemicals, aluminum or stainless steel connectors are preferable due to their corrosion-resistant properties. Moreover, the choice of material should align with the overall application to ensure compatibility and longevity.

2. Compatibility with Aluminum Profiles

Not all aluminum profile accessories are compatible with every type of aluminum profile. It is crucial to ensure that the accessories you choose are designed to fit the specific profile you are working with. For instance, T-slot profiles require T-slot nuts and bolts, while other profiles may need different types of fasteners or aluminum profile connectors. Mismatched accessories can lead to instability and compromise the structural integrity of the assembly.

Consulting with an aluminum profile accessories manufacturer can help you identify the right accessories for your project. Manufacturers often provide detailed specifications and compatibility charts, making it easier to select the appropriate components. Additionally, some manufacturers offer custom accessories tailored to specific project requirements, ensuring a perfect fit.

3. Application-Specific Requirements

The application for which the aluminum profile is being used will significantly influence the choice of accessories. For example, industrial applications may require heavy-duty aluminum profile fittings that can withstand high loads and harsh environments. In contrast, lightweight accessories may be sufficient for applications such as furniture or display stands.

Consider the following factors when selecting accessories for specific applications:

Load-bearing capacity: Ensure that the accessories can support the weight and stress they will be subjected to.

Environmental conditions: If the structure will be exposed to extreme temperatures, humidity, or chemicals, choose accessories that are resistant to corrosion and wear.

Aesthetic requirements: In some cases, the appearance of the accessories may be important, especially for applications in public spaces or retail environments.

4. Ease of Installation

Another important factor to consider is the ease of installation. Some aluminum profile accessories are designed for quick and easy assembly, while others may require specialized tools or expertise. For example, aluminum extrusion profile accessories such as T-slot nuts and bolts can be easily inserted into the profile’s slots and tightened with a standard wrench. On the other hand, more complex accessories, such as corner brackets or hinges, may require additional steps for proper installation.

Working with a reputable aluminum profile accessories manufacturer can ensure that you receive detailed installation instructions and support. Some manufacturers also offer pre-assembled kits, which can save time and reduce the risk of errors during installation.

5. Cost Considerations

Cost is always a factor when selecting aluminum profile accessories. While it may be tempting to opt for the cheapest option, it is essential to consider the long-term costs associated with maintenance, replacement, and potential structural failures. High-quality accessories may have a higher upfront cost, but they often provide better durability and performance, reducing the need for frequent replacements.

When working with an aluminum profile accessories manufacturer, inquire about bulk pricing or discounts for large orders. Many manufacturers offer competitive pricing for bulk purchases, making it more cost-effective to invest in high-quality accessories for larger projects.

Types of Aluminum Profile Accessories

1. Connectors

Aluminum profile connectors are essential for joining two or more profiles together. They come in various shapes and sizes, including L-shaped, T-shaped, and cross connectors. These connectors are typically made from aluminum or stainless steel to ensure strength and durability. When selecting connectors, it is important to choose ones that are compatible with the profile’s slot size and intended load-bearing capacity.

For heavy-duty applications, consider using reinforced connectors that provide additional support and stability. In contrast, lightweight connectors may be sufficient for smaller, less demanding projects. Consulting with an aluminum profile accessories manufacturer can help you determine the best connectors for your specific application.

2. Fittings

Aluminum profile fittings are used to secure profiles in place and provide additional support. Common fittings include corner brackets, hinges, and end caps. These fittings are designed to be easy to install and adjust, making them ideal for applications that require frequent reconfiguration or modification.

When selecting fittings, consider the specific requirements of your project. For example, corner brackets are ideal for creating rigid, 90-degree joints, while hinges allow for movement and flexibility. Aluminum extrusion profile accessories such as end caps are essential for protecting the ends of profiles and preventing debris from entering the slots.

3. Fasteners

Fasteners, such as T-slot nuts and bolts, are used to secure accessories to the aluminum profile. These fasteners are designed to slide into the profile’s slots and can be tightened with a standard wrench. It is important to choose fasteners that are compatible with the profile’s slot size and the accessories being used.

For heavy-duty applications, consider using high-strength fasteners made from stainless steel or reinforced aluminum. These fasteners provide additional strength and durability, ensuring that the structure remains stable under load.

Choosing the right aluminum profile accessories is essential for ensuring the stability, durability, and functionality of your project. By considering factors such as material composition, compatibility, application-specific requirements, ease of installation, and cost, you can make an informed decision that meets your project’s needs. Working with a reputable aluminum profile accessories manufacturer can also provide valuable guidance and support throughout the selection process.

Whether you are selecting aluminum profile connectors, fittings, or fasteners, it is important to prioritize quality and compatibility to ensure the success of your project. By following the guidelines outlined in this article, you can confidently choose the right accessories for your aluminum profile assembly.