In the realm of modern hardware, accuracy and effectiveness are principal. Each part assumes a pivotal part in guaranteeing smooth tasks and ideal execution. One such part that frequently slips by everyone's notice except assumes a critical part in calibrating modern gear is aluminum profiles. These adaptable and lightweight profiles offer the ideal answer for changing and improving different parts of modern hardware.

To really comprehend the capability of aluminum profiles, it is fundamental to dive into their properties and attributes. From their high solidarity to-weight proportion to their erosion obstruction, aluminum profiles offer a great many advantages that pursue them an optimal decision for tweaking modern gear. By understanding the complexities of these profiles, makers and architects can open their actual potential and accomplish upgraded execution in their hardware.

Key elements in calibrating modern gear lie in the legitimate usage of aluminum profiles. From changing the level and width of transport frameworks to improving the arrangement of automated arms, these profiles offer vast opportunities for customization. By utilizing the right procedures and techniques for aluminum profile changes, producers can calibrate their gear to meet explicit necessities and accomplish unmatched accuracy.

Notwithstanding, it is critical to follow best practices while using aluminum profiles for calibrating modern hardware. From choosing the right profile size and shape to considering load-bearing limits, tender loving care is fundamental. This article will dig into the different procedures, strategies, and best practices that makers and specialists ought to remember to guarantee effective adjusting of modern hardware with aluminum profiles. By carrying out these methodologies, organizations can upgrade their efficiency, lessen margin time, and eventually gain an upper hand on the lookout.

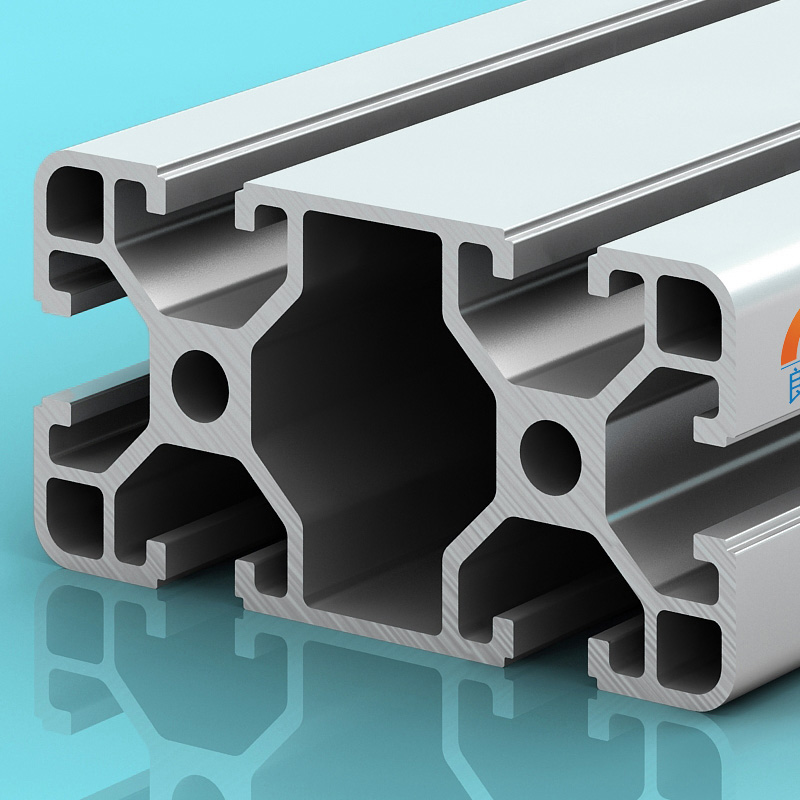

Understanding Aluminum Profiles

Aluminum profiles are a fundamental part in different ventures, offering a large number of utilizations because of their flexibility and toughness. These profiles are painstakingly planned and made to take care of explicit prerequisites and are regularly utilized in development, auto, aviation, and assembling areas.

One of the vital advantages of aluminum profiles is their lightweight nature, which makes them simple to deal with and transport. Regardless of their lightweight, they have remarkable strength and can endure weighty burdens and outrageous weather patterns. This settles on them an optimal decision for primary applications, like structure structures and emotionally supportive networks.

Notwithstanding their solidarity, aluminum profiles additionally offer magnificent consumption obstruction. This trademark is credited to the normal oxide layer that structures on the outer layer of aluminum when presented to oxygen. This oxide layer goes about as a defensive obstruction, forestalling further erosion and guaranteeing the life span of the profiles. This makes them appropriate for outside applications where openness to dampness and brutal conditions is unavoidable.

One more benefit of aluminum profiles is their adaptability in plan. They can be effectively molded and expelled into different structures, considering vast potential outcomes regarding customization. Whether it's a complex structural plan or an exact part for hardware, aluminum profiles can be custom-made to meet explicit necessities. This pursues them a well known decision among modelers, specialists, and planners who look for flexibility and feel in their tasks.

Besides, aluminum profiles are profoundly maintainable and harmless to the ecosystem. Aluminum is a recyclable material, and the energy expected to reuse it is fundamentally less contrasted with essential creation. By utilizing aluminum profiles, businesses can add to decreasing their carbon impression and advancing a roundabout economy.

Key Factors in Fine-Tuning Industrial Equipment

Calibrating modern hardware is a significant part of guaranteeing ideal execution and effectiveness in different assembling processes. There are a few key factors that assume a critical part in this cycle, and understanding them is fundamental for enterprises that depend on modern gear.

One of the vital elements in adjusting modern gear is the utilization of top notch materials, for example, aluminum profiles. Aluminum profiles are broadly utilized in the assembling business because of their great properties, including high solidarity to-weight proportion, erosion opposition, and strength. These profiles are normally utilized in the development of modern gear, for example, transports, sequential construction systems, and hardware outlines.

One more significant variable to consider is accuracy in plan and designing. Calibrating modern hardware requires careful meticulousness during the plan and designing stages. Each part and boundary should be painstakingly broke down and streamlined to guarantee consistent activity and greatest execution. This incorporates factors like the arrangement of moving parts, the adjustment of sensors and actuators, and the proper choice of materials and ointments.

Standard support and adjustment are likewise basic in calibrating modern gear. After some time, mileage can influence the exhibition of apparatus, prompting diminished proficiency and possible breakdowns. Thusly, executing an exhaustive upkeep plan is vital to keep the hardware in ideal condition. This incorporates routine investigations, grease, cleaning, and the substitution of broken down parts. Furthermore, normal alignment of sensors and control frameworks guarantees exact readings and exact control of the gear.

Moreover, the joining of cutting edge innovation and robotization frameworks is turning out to be progressively significant in tweaking modern hardware. Robotization further develops effectiveness as well as improves security and diminishes human blunder. The utilization of sensors, programmable rationale regulators (PLCs), and human-machine interfaces (HMIs) takes into consideration ongoing observing and control of different boundaries, empowering fast changes and advancement of the hardware's presentation.

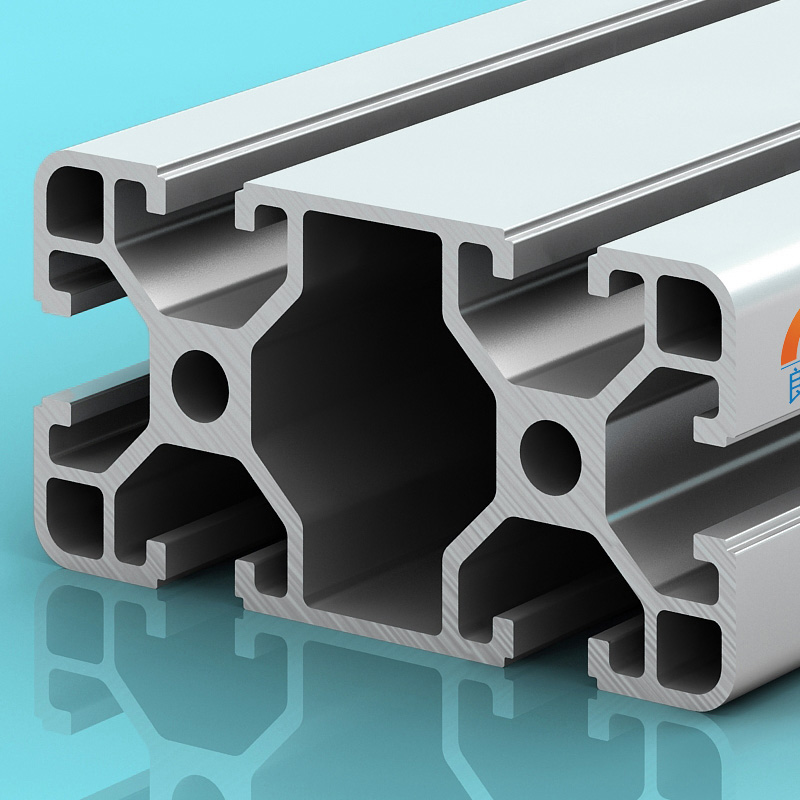

Techniques and Methods for Aluminum Profile Adjustments

Aluminum profiles assume a significant part in a great many ventures, including development, transportation, and assembling. The capacity to change these profiles is fundamental for accomplishing the ideal usefulness and style. In this article, we will investigate different strategies and techniques for aluminum profile changes.

One normal strategy for changing aluminum profiles is cutting. Whether it's a basic straight cut or a more perplexing calculated cut, exact slicing is important to guarantee an ideal fit. High level cutting devices and hardware take into consideration precise and clean cuts, limiting the requirement for extra alterations.

One more strategy for changing aluminum profiles is bowing. This strategy is especially helpful while making bended or adjusted profiles for engineering purposes. Different twisting procedures, like virus bowing and hot bowing, can be utilized in light of the particular prerequisites of the task. Care should be taken to guarantee that the honesty of the aluminum isn't compromised during the bowing system.

Joining aluminum profiles is one more essential part of their change. Different strategies, like welding, glue holding, and mechanical securing, can be utilized to consolidate aluminum profiles. The decision of joining technique relies upon elements like the heap bearing limit, toughness, and tasteful prerequisites of the eventual outcome.

Surface treatment is one more significant part of aluminum profile changes. The outer layer of aluminum profiles can be treated through processes like anodizing, powder covering, or painting. These medicines improve the presence of the profiles as well as give insurance against erosion and wear.

Notwithstanding these procedures, accuracy machining can be utilized to change aluminum profiles. This includes utilizing particular apparatus to plant, drill, or tap the profiles to accomplish explicit aspects or highlights. Accuracy machining takes into account perplexing changes and guarantees the most elevated level of exactness and quality.

Best Practices for Fine-Tuning Industrial Equipment with Aluminum Profiles

With regards to tweaking modern hardware, one material that stands apart for its flexibility and execution is aluminum profiles. These profiles offer a large number of advantages for modern applications, pursuing them a famous decision among producers and designers. In this article, we will investigate the accepted procedures for using aluminum profiles in modern gear and how they can be upgraded for greatest effectiveness.

One of the critical benefits of utilizing aluminum profiles is their lightweight yet solid nature. This makes them ideal for applications where weight decrease is critical without settling on strength. By integrating aluminum profiles into modern gear, producers can accomplish a harmony among sturdiness and spryness, bringing about superior execution.

One more significant viewpoint to consider while tweaking modern gear with aluminum profiles is the simplicity of customization. Aluminum profiles can be effortlessly shaped and molded by unambiguous prerequisites, considering more prominent adaptability in plan. This empowers architects to make hardware that fits impeccably into interesting spaces or addresses explicit necessities. Whether it's planning transport frameworks, workstations, or mechanical production systems, aluminum profiles offer vast opportunities for customization.

Notwithstanding customization, aluminum profiles likewise offer phenomenal erosion opposition. This is especially significant in modern settings where hardware is presented to cruel conditions or synthetic substances. By utilizing aluminum profiles, makers can guarantee that their hardware stays tough and dependable, even in testing conditions.

To improve the utilization of aluminum profiles in modern gear, taking into account the appropriate establishment techniques is fundamental. Meticulousness during establishment guarantees that the profiles are safely secured, limiting the gamble of any primary issues or mishaps. This ensures the security of laborers as well as drags out the life expectancy of the gear.

Besides, to completely bridle the advantages of aluminum profiles, customary support is significant. This incorporates examining the profiles for any indications of mileage, cleaning them consistently, and resolving any issues instantly. By following these support rehearses, makers can expand the life expectancy of their gear and amplify its exhibition.

Conclusion

In conclusion, aluminum profiles offer numerous advantages in terms of strength, corrosion resistance, flexibility, and sustainability. Their lightweight nature, coupled with exceptional durability, makes them a preferred choice in various industries. Whether it's for construction, automotive, aerospace, or manufacturing applications, aluminum profiles provide the necessary strength and reliability. With their ability to be customized and their positive environmental impact, it's no wonder that aluminum profiles continue to be a popular choice for both professionals and consumers alike.