PRODUCTION DESCRIPTION

Specifications:

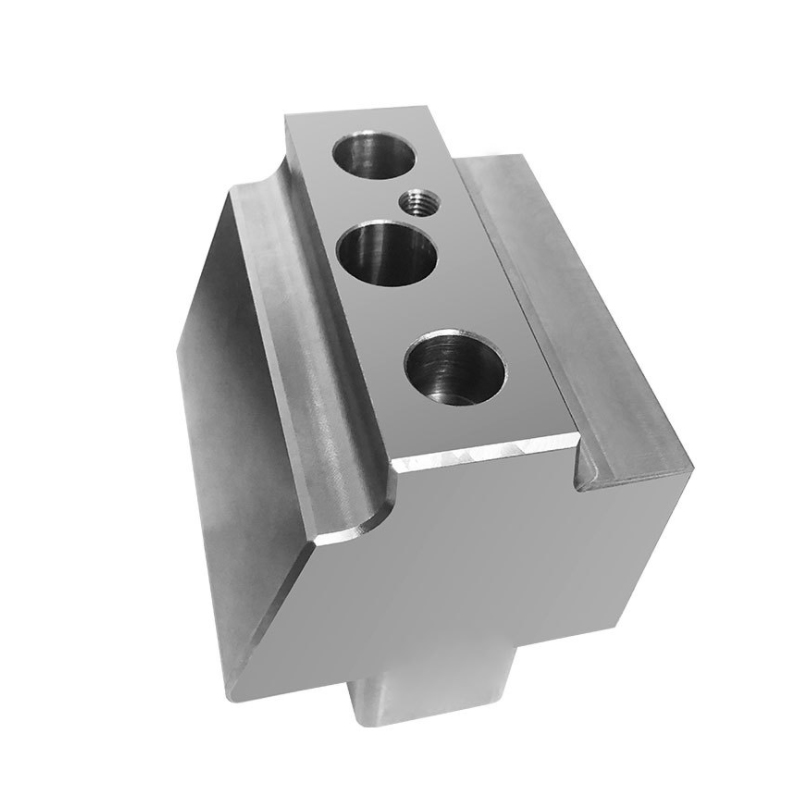

1.OEM & ODM 2.High Quality & Precision

3.Competitive Price

4.Large Quantity Production Capacity

5.Short Delivery Time

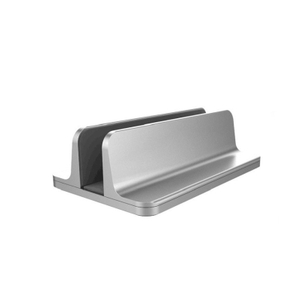

6.Optional Materials:Aluminum,Brass,Copper,Stainless Steel etc

8.Specification Is Customized 9.LOGO Can Be Customized

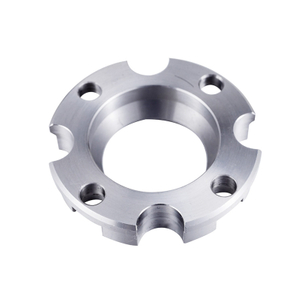

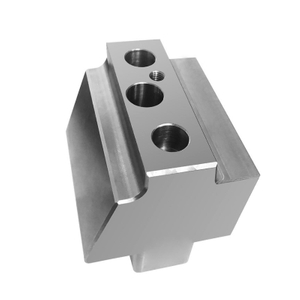

9.Processing Type: Metal Stamping Bending Parts, Metal Stamping Drawing Parts, Metal Stamping Parts

10.Samples: Stamping Hand samples Are Available To Reduce Costing

| We Support Custom CNC Machining Parts of Most Materials |

(Non- Standard Parts) |

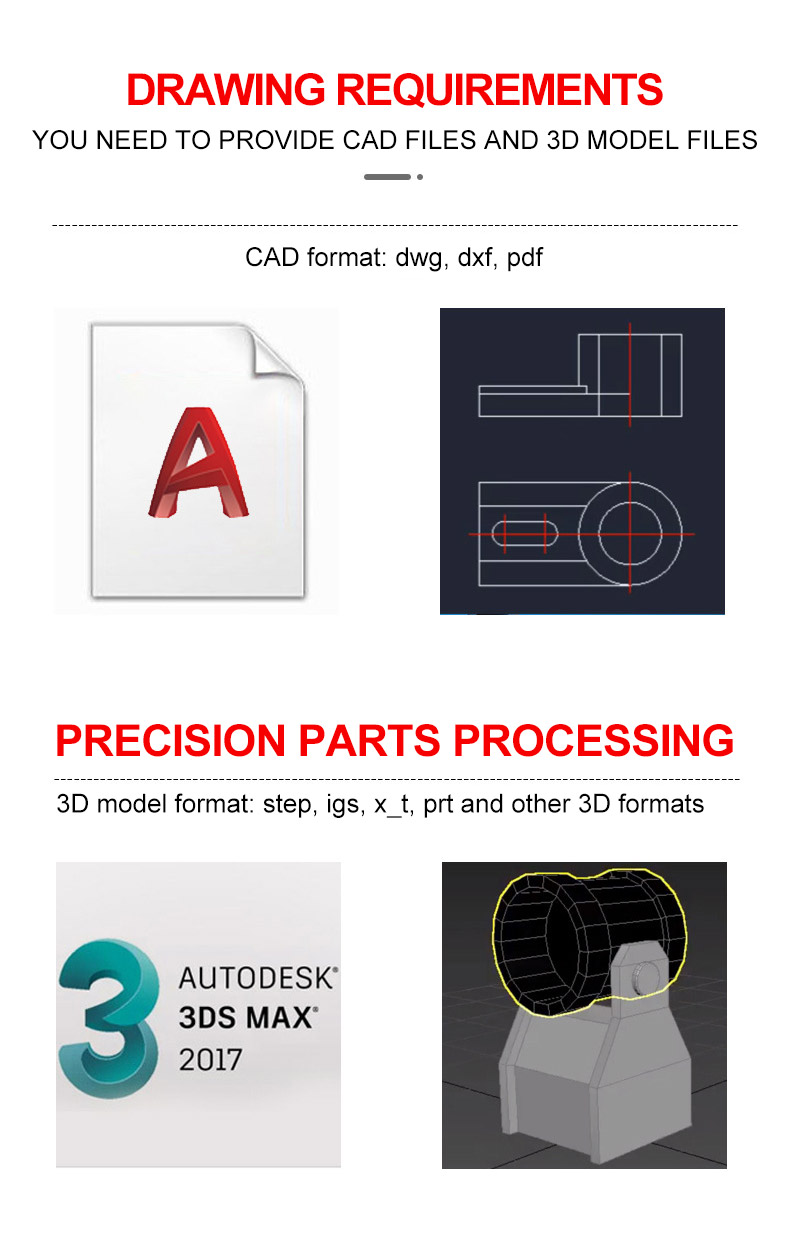

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance | +/-0.005 - 0.01mm(Custonize avaiable) |

| Surface Roughness | Ra0.2 - Ra3.2(Custonize avaiable) |

| Materials Avaiable | Such as aluminum, copper, stainless steel, iron, PE, PVC, ABS, etc. |

| Surface Treatment | Such as polishing, general oxidation, hard oxidation, color oxidation, surface chamfering, tempering, quenching, etc. |

| Processing | CNC Turning, Milling, turning-milling compound, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

| Drawing | 1.) Pls provide design drawings and contact our Alibaba sales manager, if there are no drawings can send samples/sample photos to get a free quotation.

2.) To help us offer the best service for you. Pls be sure your drawings are clear and accurate(including processing quantity,

materials, precision tolerances, surface treatment, and special requirements)

|

| Our Benefits | 1.) Over 7 years of experience in CNC machining area and have a senior design and production team to offer perfect modification

suggestions.

2.) Quickly quote & Quickly Deliver.

3.) We borne 100% responsiblity for quality problems. |

Service Items

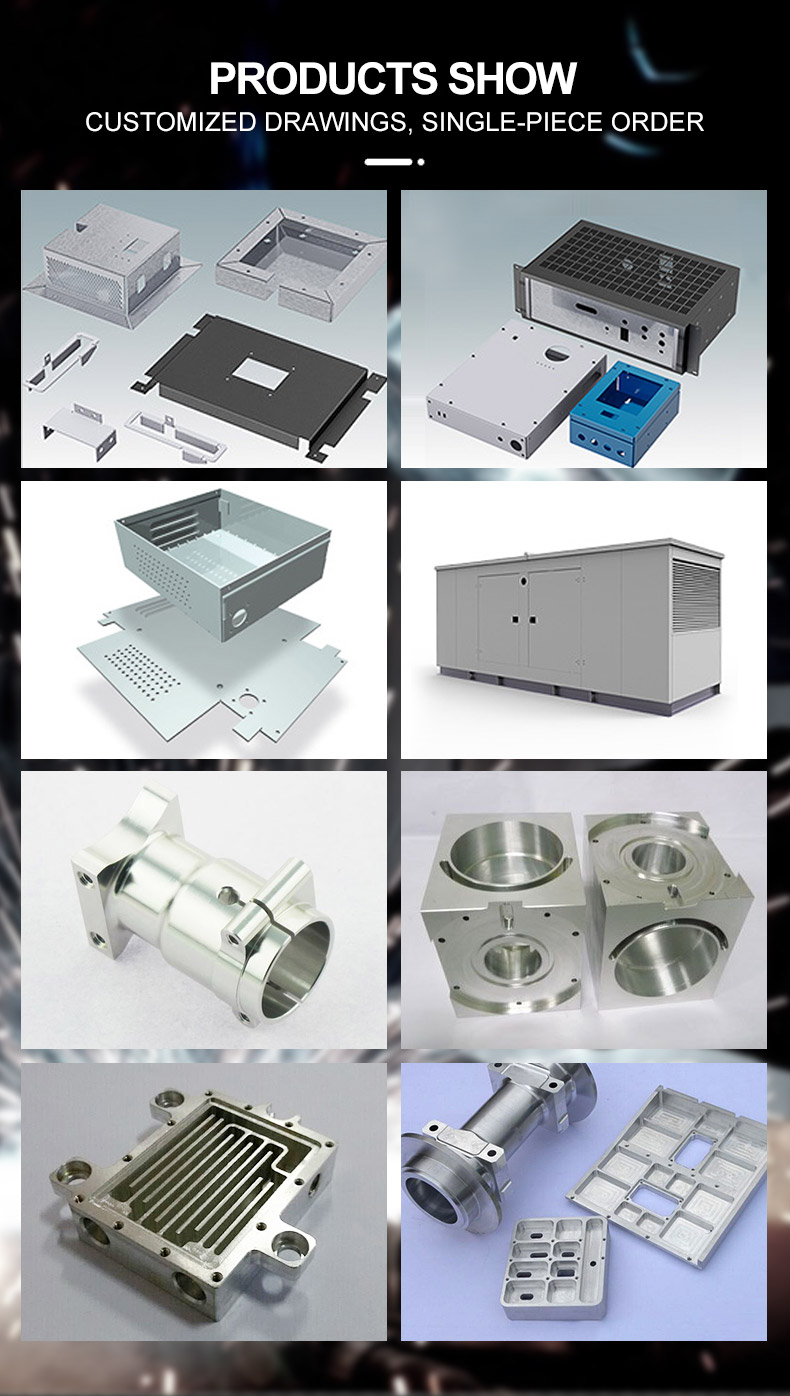

One-stop processing from sheet to finished product

Laser cutting processing, Bending processing, Welding processing, CNC machining center

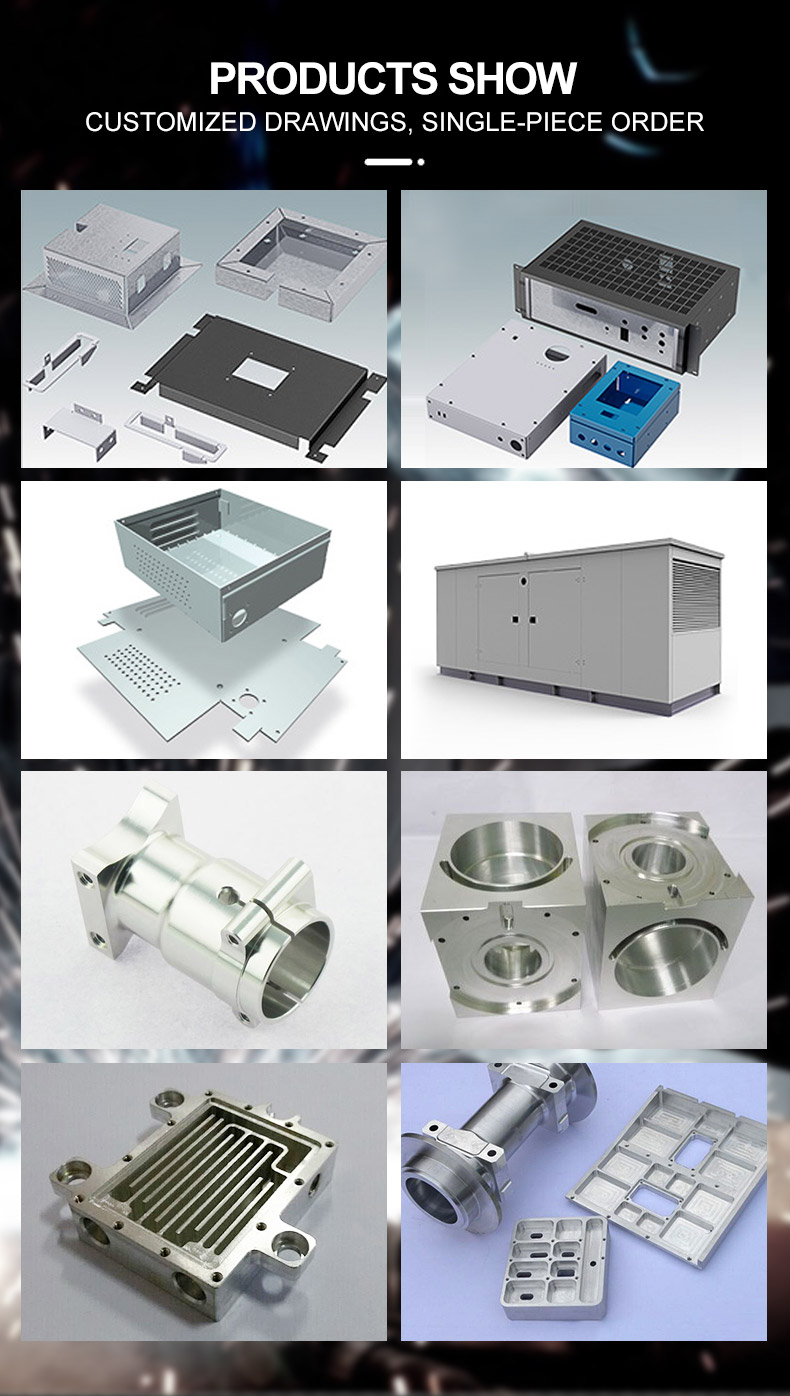

Our Advantage -- Customzied drawings, single-piece order

Technological Innovation -- Complicated and difficult curved surfacesand functional structure prototypes can be qucikly formed.

Processing Speed -- Short production cycle, fast delivery, ensure delivery in accordance with the agreed delivery date.

Product Quality -- Good quality, guaranteed material accuracty up to 0.02mm to 0.1mm.

Highly Confidential -- Multiple confidentiality measures protect customer information, more assured.

Advanced Equipment -- One-stop processing

Metal Laser cutting, Metal bending/folding, CNC machining

PARTNER

With 8 years experience, Our customers all over the world are satisfied with our high quality and service. We do long term cooperation with our customers and achieve mutual benefits.

langle Aluminium has exported to over 54 countries and achieved good reputation with its high quality, reasobale price and professional service.

COMPANY INTRODUCTION

langle Aluminum is a manufacturer specializing in industrial application building systems, non-standard automation, workstations, machine guards, stair platforms, metal guardrails, display racks, etc.

langle can provide a full range of service product design, manufacturing, stocking, and on-time delivery, making us a "one-stop" shop with a complete system, and an ideal space for you to control costs and provide more efficient work projects.

PACKING PROCESS

Packing method is EPE foam and Kraft Paper.

Inside: EPE Foam to protect the Aluminium Profiles from the impacting.

Outside: Kraft paper to protect the aluminium profiles from the water and ensure the tight of the package.

FAQ

Q1: What’s the standard length of your profiles be shipping?

A: The standard length of profiles is 6020mm, we can cut to specific length to meet your project demand.

Q2: What’s your MOQ?

A: We have no MOQ for our new customers, we are accepting small order to support your trial order, new design, marketing development.

Q3: Can you offer free sample?

A: Yes, we can provide free sample, but we are prefer to charge the freight cost if you do not have an international express account for transfer.

Q4: What’s the lead time for small order and mass production?

A: 1~3 working days for small order, and 3~15 working days for mass production of material, and the final lead time will be subject to each individual invoice.

Q5: What certification do you have?

A: We have ISO 9001 certificate.

Q6 What kind of deep process can you do ?

A:CNC, drilling, milling, cutting, welding, bending, assembling .