The renewable energy sector is experiencing a surge in demand, with an increasing number of countries committing to carbon-neutral goals and investing heavily in solar energy. This expansion is attributed to the declining costs of solar power, the growing demand for energy, and the supportive government policies that encourage the adoption of solar technology. As a result, the global solar photovoltaic market is projected to grow at a compound annual growth rate (CAGR) of 8.5% from 2022 to 2030, reaching a market size of USD 223.3 billion by 2030, according to a report by Grand View Research.

In this context, custom aluminum profiles are becoming increasingly important in the design and manufacturing of solar photovoltaic systems. These profiles are tailored to meet the specific requirements of solar panels, ensuring optimal performance, durability, and cost-effectiveness.

Understanding Custom Aluminum Profiles

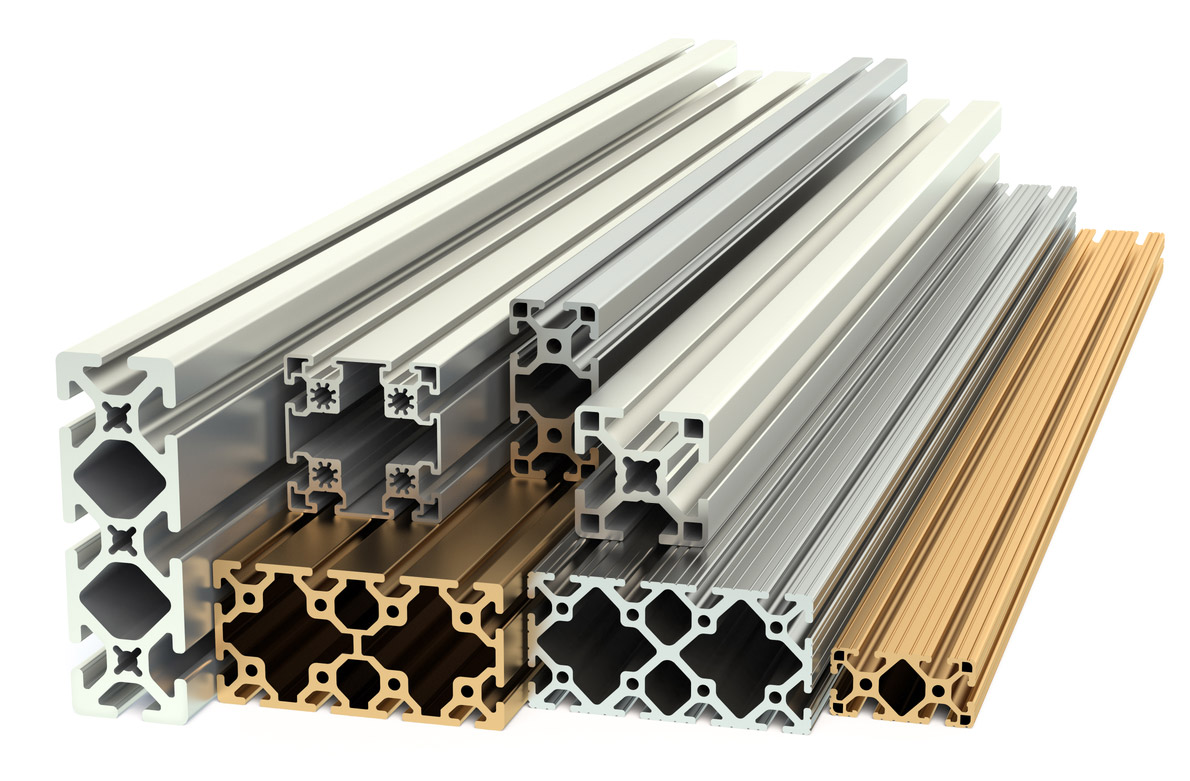

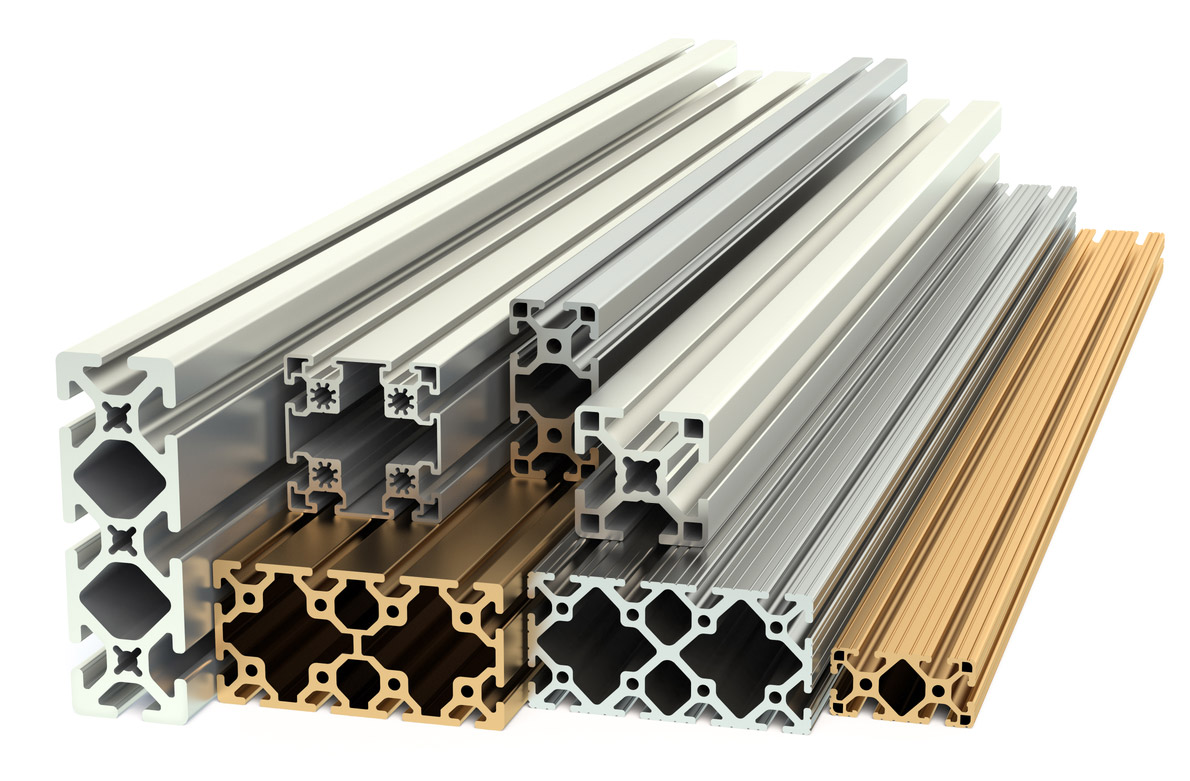

Aluminum profiles are pre-designed shapes used in various applications, including construction, manufacturing, and transportation. These profiles are created through an extrusion process where aluminum is forced through a die, resulting in a long, continuous shape that can be cut to size. This process allows for the creation of complex shapes and sizes, making aluminum profiles highly versatile and suitable for a wide range of applications.

Custom aluminum profiles, on the other hand, are specifically designed to meet the unique requirements of a particular project or application. This customization can involve creating specific shapes, sizes, and features that are not available with standard aluminum profiles. Custom profiles are particularly beneficial in the solar photovoltaic industry, where the design and functionality of the solar panel frames and mounting systems are crucial for maximizing efficiency and durability.

The importance of custom aluminum profiles in solar photovoltaic systems lies in their ability to enhance the performance and longevity of solar panels. For instance, custom profiles can be designed to improve the structural integrity of solar panels, ensuring they can withstand harsh weather conditions. Additionally, custom profiles can be tailored to facilitate better heat dissipation, which is essential for maintaining the efficiency of solar panels over time.

Key Features of Custom Aluminum Profiles for Solar PV Systems

When designing custom aluminum profiles for solar photovoltaic systems, several key features are taken into consideration to ensure optimal performance and durability.

One of the most critical design considerations is the structural integrity of the solar panel frame. The frame must be strong enough to support the weight of the solar panel and withstand environmental stresses such as wind and snow loads. Custom aluminum profiles can be designed with specific cross-sectional shapes that enhance the strength and rigidity of the frame without adding unnecessary weight.

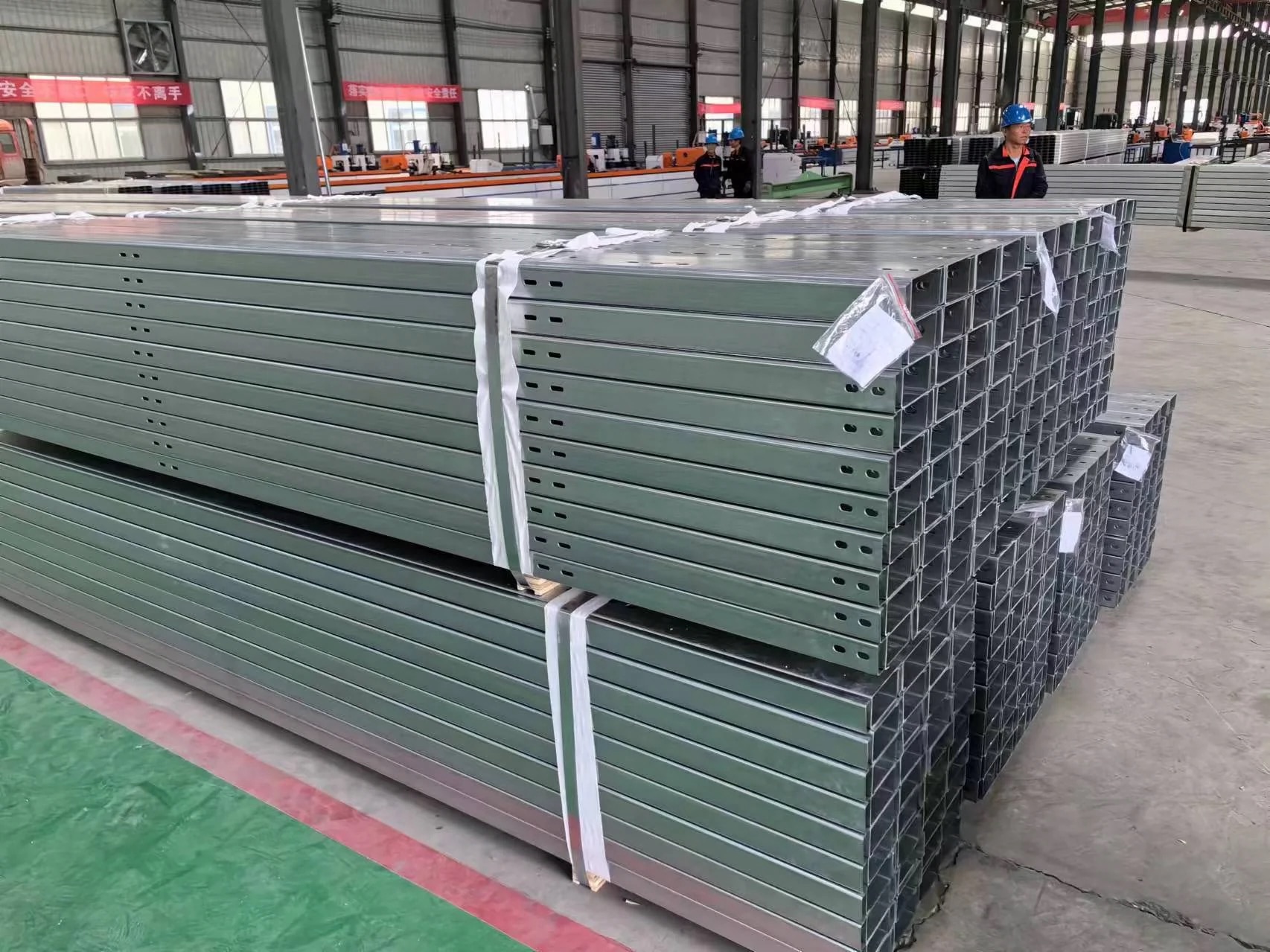

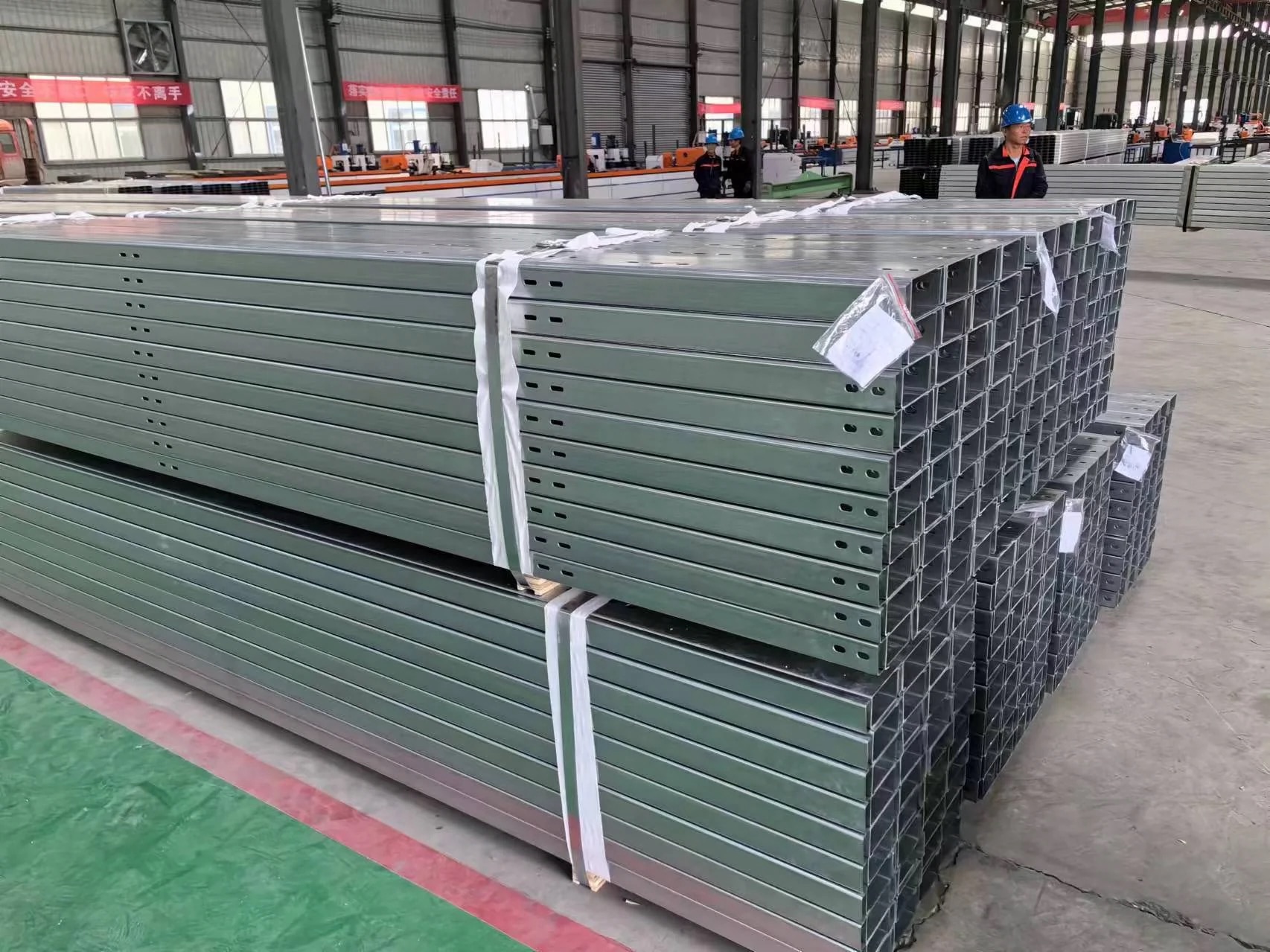

Another important feature is the integration of mounting solutions. Custom aluminum profiles can be designed with built-in mounting features that simplify the installation process and ensure a secure fit. These features can include slots for T-bolts, pre-drilled holes, and other mounting accessories that facilitate quick and easy installation.

Thermal management is also a key consideration in the design of custom aluminum profiles for solar photovoltaic systems. Aluminum is an excellent conductor of heat, which makes it ideal for dissipating heat generated by solar panels. Custom profiles can be designed with larger surface areas or specific geometries that enhance heat dissipation, thereby improving the efficiency and lifespan of the solar panels.

Additionally, custom aluminum profiles can be designed to be lightweight, which is crucial for reducing transportation costs and making the installation process easier. This lightweight design is achieved by strategically placing material in areas where it is most needed for strength, while minimizing material in less critical areas.

Finally, custom aluminum profiles can be designed to be corrosion-resistant, which is essential for ensuring the longevity of solar photovoltaic systems, especially in harsh environmental conditions. This can be achieved through the use of anodizing or other protective coatings that enhance the durability of the aluminum profiles.

Advantages of Using Custom Aluminum Profiles in Solar PV Systems

The use of custom aluminum profiles in solar photovoltaic systems offers several significant advantages that contribute to the overall efficiency, durability, and cost-effectiveness of solar energy solutions.

One of the primary advantages is the enhanced efficiency of solar panels. Custom aluminum profiles can be designed to optimize the alignment and positioning of solar panels, ensuring they receive maximum sunlight exposure. This optimization can significantly increase the energy conversion efficiency of solar panels, leading to higher energy output.

In addition to improving efficiency, custom aluminum profiles also extend the lifespan of solar photovoltaic systems. By incorporating design features such as improved drainage, ventilation, and protection against environmental factors, custom profiles can reduce the risk of damage from weather-related stresses. This durability translates into lower maintenance and replacement costs over the life of the solar system.

Cost-effectiveness is another major benefit of using custom aluminum profiles in solar PV systems. While the initial investment in custom profiles may be higher than standard profiles, the long-term savings in terms of reduced maintenance, increased efficiency, and extended lifespan far outweigh the upfront costs. Moreover, the ability to design profiles that are tailored to specific project requirements can lead to more efficient use of materials, further reducing costs.

Custom aluminum profiles also offer the advantage of design flexibility. This flexibility allows engineers and designers to create innovative solutions that can be easily integrated into existing solar PV systems or adapted to new designs. Whether it’s a unique mounting solution or a specialized frame design, custom profiles enable the implementation of creative ideas that enhance the functionality and aesthetics of solar panels.

Finally, the use of custom aluminum profiles in solar photovoltaic systems is environmentally friendly. Aluminum is a highly recyclable material, and the ability to design profiles that are optimized for recycling at the end of their life cycle contributes to the sustainability of solar energy solutions. Additionally, the improved efficiency and longevity of solar panels reduce the environmental impact of solar energy by maximizing the energy generated per unit of material used.

Future Trends in Custom Aluminum Profiles for Solar PV Systems

The future of custom aluminum profiles in solar photovoltaic systems is poised for significant advancements, driven by ongoing innovations in material science, manufacturing processes, and renewable energy technologies.

One of the most promising trends is the development of advanced materials and coatings that enhance the properties of aluminum profiles. These materials can improve corrosion resistance, thermal conductivity, and mechanical strength, making aluminum profiles even more suitable for demanding solar applications. For instance, new anodizing techniques can create thicker, more durable coatings that protect aluminum profiles from harsh environmental conditions while maintaining their lightweight and thermal efficiency.

In addition to material advancements, manufacturing processes for custom aluminum profiles are becoming more sophisticated. Techniques such as 3D printing and additive manufacturing are being explored to create complex shapes and designs that were previously difficult or impossible to achieve with traditional extrusion methods. These advanced manufacturing techniques can reduce waste, lower production costs, and enable the rapid prototyping of custom designs, leading to faster innovation and deployment of solar photovoltaic systems.

The integration of digital technologies and automation in the design and manufacturing of custom aluminum profiles is another trend shaping the future of solar PV systems. Digital design tools and simulation software allow engineers to optimize profile designs for specific performance criteria, such as aerodynamic efficiency or structural integrity. Automated extrusion lines and robotic assembly systems streamline the production process, ensuring high precision and consistency in the manufacturing of custom profiles.

Furthermore, the growing emphasis on sustainability and circular economy principles is driving the development of eco-friendly aluminum profiles. This includes the use of recycled aluminum, the design of profiles for easy disassembly and recycling at the end of their life cycle, and the incorporation of bio-based or non-toxic coatings that minimize environmental impact.

Finally, the increasing adoption of smart technologies and Internet of Things (IoT) solutions in the renewable energy sector is influencing the design of custom aluminum profiles. Smart solar panels with embedded sensors and connectivity features require specialized profiles that can accommodate these technologies without compromising the performance or aesthetics of the solar system.

These trends are not only enhancing the performance and sustainability of solar photovoltaic systems but also expanding the potential applications of custom aluminum profiles in the renewable energy sector. As solar technology continues to evolve, the role of custom aluminum profiles will become increasingly critical in driving innovation and achieving the ambitious global renewable energy targets.

Conclusion

In conclusion, custom aluminum profiles are revolutionizing the solar photovoltaic industry by providing tailored solutions that enhance the efficiency, durability, and sustainability of solar systems. These profiles offer numerous advantages, including improved structural integrity, optimized thermal management, and design flexibility, which contribute to the overall performance and longevity of solar panels.

The future of custom aluminum profiles in solar photovoltaic systems is bright, with ongoing advancements in materials, manufacturing processes, and digital technologies. These innovations are driving the development of more efficient, durable, and eco-friendly solar solutions that align with the global push towards renewable energy and carbon neutrality.

As the renewable energy sector continues to grow, the demand for customized solutions that meet specific project requirements will increase. Custom aluminum profiles will play a pivotal role in addressing this demand, enabling the design and manufacturing of solar photovoltaic systems that are not only efficient and durable but also environmentally sustainable.

For industry professionals, investing in custom aluminum profiles is a strategic decision that can lead to significant long-term benefits. By leveraging the advantages of custom profiles, solar PV system designers and manufacturers can create innovative solutions that stand out in the competitive renewable energy market, ultimately contributing to the global transition towards a cleaner, more sustainable future.