This article explores the world of custom aluminum profiles, which are essential components in various industrial applications. Customization is often necessary to meet the unique requirements of each application. The article covers the basics of aluminum profiles, their versatility, and customization options. The manufacturing process for custom aluminum profiles is discussed, including design, engineering, extrusion, and finishing. Real-life case studies demonstrate how custom profiles have been used to overcome unique challenges and improve overall performance. Choosing the right aluminum profile manufacturer is also essential to achieving desired results. By partnering with an experienced manufacturer with technical expertise, organizations can ensure they receive custom profiles that meet their precise requirements and specifications. Understanding the potential of custom aluminum profiles can unlock new opportunities for innovation and efficiency in industries such as construction, automotive, and aviation.

Understanding Aluminum Profiles

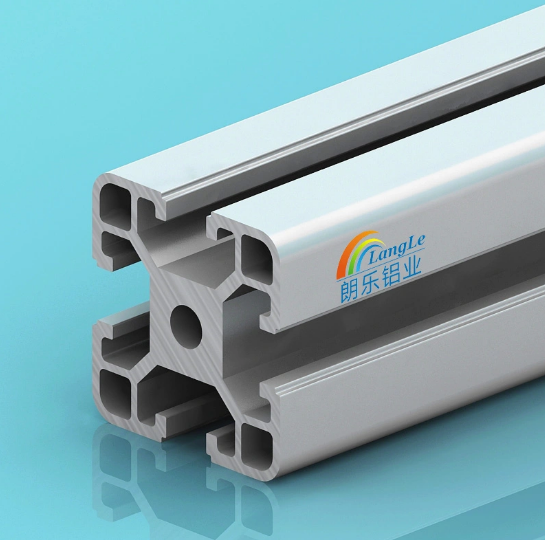

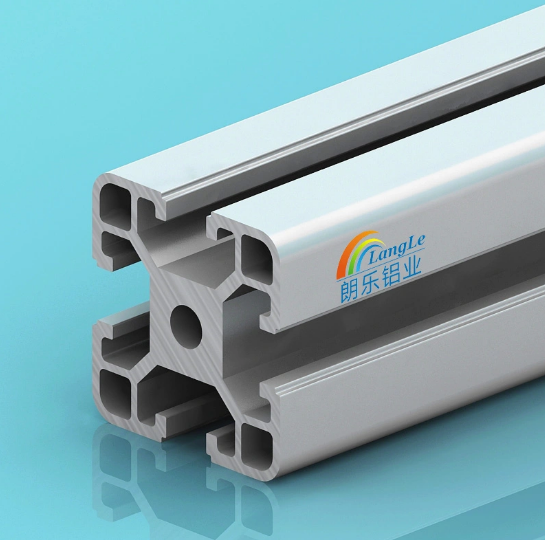

Aluminum profiles are a fundamental part in different businesses, going from development to auto. These profiles are flexible, sturdy, and lightweight, pursuing them an optimal decision for a large number of utilizations. Understanding the various parts of aluminum profiles can assist enterprises with settling on informed choices with regards to choosing the right materials for their ventures.

One of the vital benefits of aluminum profiles is their customization choices. Custom aluminum profiles can be custom fitted to meet explicit plan prerequisites, guaranteeing an ideal fit for any undertaking. Whether it is an interesting shape or a particular size, makers can make profiles that match the ideal determinations. This degree of customization permits ventures to upgrade their plans and accomplish the ideal usefulness.

Notwithstanding customization, aluminum profiles offer extraordinary solidarity to-weight proportion. In spite of being lightweight, these profiles show magnificent strength and sturdiness. This makes them appropriate for applications where primary respectability is essential. From structural systems to transportation parts, aluminum profiles give a solid and dependable arrangement.

Also, aluminum profiles are profoundly erosion safe. The normal oxide layer that structures on the outer layer of aluminum gives a defensive obstruction against erosion, broadening the life expectancy of the profiles. This consumption opposition makes aluminum profiles ideal for outside applications or conditions with high stickiness or substance openness.

One more advantage of aluminum profiles is their recyclability. Aluminum is an economical material that can be reused endlessly without losing its properties. This lessens the ecological effect as well as offers cost reserve funds over the long haul. By picking aluminum profiles, enterprises can add to a greener future while as yet keeping up with the expected exhibition and quality.

Customization Options for Aluminum Profiles

With regards to picking aluminum profiles for different applications, customization choices assume a pivotal part. Custom aluminum profiles offer a scope of advantages, including upgraded usefulness, style, and cost-productivity. In this article, we will investigate the different customization choices accessible for aluminum profiles.

One of the key customization choices for aluminum profiles is the decision of shape and size. Aluminum profiles can be expelled into different shapes, like square, rectangular, round, or even complex calculations. This adaptability takes into account the formation of tweaked profiles to fit explicit venture prerequisites. Whether it's for building purposes, modern applications, or auto parts, custom aluminum profiles can be custom-made to meet the ideal particulars.

Another significant customization choice is the surface completion. Aluminum profiles can be done in different ways, including anodizing, powder covering, or painting. Anodizing is a well known decision as it gives a defensive layer to the aluminum, making it more impervious to erosion and wear. Powder covering and painting, then again, offer an extensive variety of variety choices, considering more noteworthy plan flexibility and tasteful allure.

Moreover, custom aluminum profiles can likewise be manufactured with extra elements and embellishments. These can incorporate scores, spaces, openings, or even coordinated useful components, for example, heat sinks or mounting sections. These highlights add to the flexibility and convenience of the profiles, making them reasonable for many applications.

Notwithstanding shape, size, surface completion, and extra highlights, custom aluminum profiles can likewise be custom-made with regards to compound choice. Different aluminum amalgams offer shifting properties, like strength, consumption opposition, and conductivity. By choosing the fitting compound, the exhibition of the profiles can be upgraded for explicit applications. This guarantees that the profiles meet the expected primary and practical prerequisites.

The Process of Creating Custom Aluminum Profiles

Making custom aluminum profiles is a fastidious cycle that requires accuracy and skill. These profiles are generally utilized in different ventures, from development to auto, because of their sturdiness and adaptability. In this article, we will dig into the bit by bit course of assembling custom aluminum profiles.

The most important phase in making custom aluminum profiles is planning. This includes working intimately with the client to figure out their particular necessities and determinations. The plan stage incorporates deciding the ideal shape, size, and aspects of the profiles. High level PC supported plan (computer aided design) programming is utilized to make itemized outlines that act as an aide all through the assembling system.

When the plan is settled, the following stage is choosing the suitable aluminum compound. The decision of compound relies upon variables like strength, consumption opposition, and cost-viability. Aluminum composites, for example, 6061 and 6063 are regularly utilized for custom profiles because of their great mechanical properties and simplicity of manufacture.

In the wake of choosing the compound, the subsequent stage is expulsion. Expulsion is a cycle wherein the aluminum billet is warmed and constrained through a molded bite the dust to make the ideal profile. The warmed aluminum is pushed through the bite the dust under high tension, bringing about the arrangement of the custom profile. This cycle takes into account the formation of complicated shapes and unpredictable plans.

When the profiles are expelled, they go through different completing cycles to improve their appearance and strength. These cycles might incorporate cutting, deburring, machining, and surface treatment. Slicing is finished to accomplish the ideal length of the profiles, while deburring eliminates any sharp edges or burrs. Machining includes penetrating openings or adding extra elements to the profiles according to the client's necessities. Surface treatment, for example, anodizing or powder covering, is applied to give erosion opposition and work on the stylish allure of the profiles.

The last move toward making custom aluminum profiles is quality control. Each profile is entirely assessed to guarantee it meets the predefined aspects and quality guidelines. This remembers checking for any deformities or blemishes for the profiles. Just profiles that pass the severe quality control process are endorsed for conveyance to the client.

Applications of Custom Aluminum Profiles in Various Industries

Custom aluminum profiles assume a critical part in a large number of businesses, giving endless applications and advantages. These adaptable profiles offer gigantic customization choices and extraordinary solidness, going with them an optimal decision for different modern necessities.

One of the most conspicuous utilizations of custom aluminum profiles is in the development business. These profiles are widely utilized in the manufacture of entryways, windows, and drapery walls. The lightweight idea of aluminum makes it simpler to deal with during establishment, while its high strength guarantees dependable execution. Also, custom aluminum profiles can be exactly custom-made to meet explicit plan necessities, permitting engineers and developers to make remarkable and outwardly engaging designs.

Another industry that broadly uses custom aluminum profiles is the transportation area. Aluminum profiles are broadly utilized in the assembling of airplane, autos, and rail line vehicles. The lightweight idea of aluminum fundamentally diminishes the general load of these vehicles, bringing about superior eco-friendliness and decreased fossil fuel byproducts. Moreover, the outstanding solidarity to-weight proportion of aluminum profiles guarantees upgraded security and primary trustworthiness in these transportation frameworks.

Custom aluminum profiles additionally track down their applications in the gadgets business. With the rising interest for minimized and lightweight electronic gadgets, aluminum profiles offer an incredible arrangement. These profiles are utilized in the creation of intensity sinks, nooks, and edges for different electronic parts. The astounding warm conductivity of aluminum disseminates heat effectively, guaranteeing ideal execution and life span of electronic gadgets.

In the environmentally friendly power area, custom aluminum profiles are used in the development of sunlight based charger edges and mounting frameworks. Aluminum's erosion opposition and lightweight nature go with it an optimal decision for outside establishments. These profiles offer underlying help and solidness to sun powered chargers, guaranteeing their appropriate working and life span. Additionally, aluminum's recyclability lines up with the maintainability objectives of the sustainable power industry.

Custom aluminum profiles likewise have applications in the marine business. They are utilized in the manufacture of boat bodies, poles, and other primary parts. Aluminum's protection from consumption in marine conditions pursues it an amazing decision for these applications. Moreover, the lightweight idea of aluminum profiles adds to further developed eco-friendliness and mobility of boats.

Case Studies: Real-life Examples of Custom Aluminum Profiles

Contextual analyses: Genuine Instances of Custom Aluminum Profiles

In the present current world, custom aluminum profiles have turned into a fundamental piece of different businesses. These profiles offer a large number of advantages, including high solidarity to-weight proportion, erosion obstruction, and flexibility. From development to auto, aviation to hardware, the utilizations of custom aluminum profiles are boundless. To additionally comprehend the significance and viability of these profiles, we should jump into some genuine contextual investigations.

One imperative contextual investigation includes the development business. A main development organization was confronting difficulties in tracking down the ideal material for their structure veneers. They required an answer that wouldn't just endure cruel weather patterns yet additionally give a stylishly satisfying appearance. Custom aluminum profiles acted the hero! With their capacity to be formed into different shapes and sizes, these profiles were utilized to make staggering exteriors that upgraded the structure's style as well as given solidness and climate obstruction.

Continuing on toward the auto business, a famous vehicle maker was searching for ways of diminishing the heaviness of their vehicles without settling on strength and wellbeing. Custom aluminum profiles ended up being a definitive arrangement. By supplanting conventional steel parts with lightweight aluminum profiles, the vehicle producer had the option to accomplish huge weight decrease, bringing about superior eco-friendliness and better in general execution. These profiles were utilized in different pieces of the vehicles, including skeleton, body boards, and suspension frameworks.

Another fascinating contextual investigation includes the airplane business. An airplane maker was looking for a material that could endure outrageous temperatures and give superb strength. Once more custom aluminum profiles demonstrated their value. These profiles were utilized in the development of airplane wings and fuselages, where they offered outstanding solidarity to-weight proportion and protection from erosion. The utilization of custom aluminum profiles decreased the heaviness of the airplane as well as expanded its eco-friendliness, prompting cost investment funds and natural advantages.

In the domain of gadgets, a main innovation organization was searching for a material that could scatter heat effectively and give electromagnetic safeguarding. Custom aluminum profiles with their magnificent warm conductivity and electrical conductivity turned into the best decision. These profiles were utilized in the assembling of intensity sinks, nooks, and connectors, guaranteeing ideal execution and assurance for electronic parts.

These contextual analyses feature the adaptability and viability of custom aluminum profiles in different businesses. The utilization of these profiles has reformed development, auto, aviation, and hardware areas, offering various benefits like strength, toughness, weight decrease, and erosion opposition. As innovation keeps on propelling, the interest for custom aluminum profiles is supposed to develop, making them a fundamental part in endless applications.

Choosing the Right Aluminum Profile Manufacturer

Picking the right aluminum profile producer is urgent for any undertaking that requires custom aluminum profiles. With such countless makers on the lookout, finding the ideal fit for your particular needs can overpower. Nonetheless, by taking into account a couple of key variables, you can settle on an educated choice and guarantee the outcome of your venture.

Perhaps the earliest thing to consider while picking an aluminum profile maker is their experience and ability. Search for a maker that has a demonstrated history of delivering great custom aluminum profiles. This not set in stone by assessing their portfolio and client audits. A maker with broad experience will have a superior comprehension of the business' necessities and will actually want to convey items that meet your determinations.

One more significant variable to consider is the maker's creation abilities. Contingent upon the intricacy and size of your venture, you really want to guarantee that the producer has the important gear and assets to deal with it. A maker with current and high level hardware will actually want to deliver custom aluminum profiles all the more proficiently and precisely. Furthermore, check in the event that they have a solid store network to guarantee convenient conveyance of your orders.

Quality affirmation is one more basic viewpoint to consider. A legitimate aluminum profile maker will have a rigid quality control process set up to guarantee that each item satisfies the necessary guidelines. This will incorporate careful examinations and tests at different phases of the assembling system. By picking a maker that focuses on quality, you can be certain that the custom aluminum profiles you get will be sturdy and dependable.

Cost is likewise a critical thought. While it is vital for stay affordable enough for you, thinking twice about quality is similarly significant not. Look at statements from changed makers, yet in addition consider the worth they give. A somewhat higher forthright expense might be worth the effort in the event that the producer offers prevalent quality and magnificent client care.

Ultimately, consider the producer's client care and after-deals administration. A dependable producer will be receptive to your inquiries and give help in the interim - from plan to conveyance. They ought to likewise offer guarantees on their items, showing their trust in their craftsmanship.

Conclusion

In conclusion, aluminum profiles offer versatility, customization options, and exceptional properties that make them a reliable and sustainable choice for various industries. Customization options for aluminum profiles are extensive and crucial for achieving desired outcomes. The process of creating custom aluminum profiles involves designing, selecting the appropriate alloy, extrusion, finishing, and quality control. Custom aluminum profiles have diverse applications across industries and continue to play a vital role in shaping and improving manufacturing processes and products. They have proven to be a game-changer in multiple industries, meeting specific requirements and delivering exceptional results. Choosing the right aluminum profile manufacturer is crucial for project success, considering factors such as experience, production capabilities, quality assurance, cost, and customer support.