Mechanized Testing Hardware (ATE) has turned into an indispensable piece of the assembling system, permitting organizations to guarantee the quality and dependability of their items. To fabricate proficient and successful ATE, it is pivotal to have areas of strength for a, which is where aluminum profiles become an integral factor. Understanding the advantages and attributes of aluminum profiles is fundamental for planning and building ATE that meets the particular necessities of the assembling business. This article investigates the different parts of building ATE with aluminum profiles, including the plan contemplations, procedures for improving execution and usefulness, and the significance of normal support and upkeep. By using aluminum profiles, makers can make adaptable and strong ATE that can endure the afflictions of testing and give exact outcomes. Whether you are new to the idea of ATE or hoping to advance your current gear, this article will give important experiences into the universe of building robotized testing hardware with aluminum profiles.

Understanding Aluminum Profiles

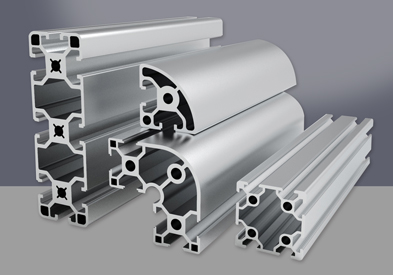

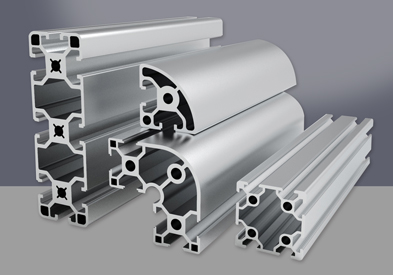

Aluminum profiles are a fundamental part in different enterprises, including development, auto, aviation, and assembling. These profiles are produced using aluminum composites, which offer a remarkable mix of solidarity, toughness, and lightweight properties. Understanding the various sorts and utilizations of aluminum profiles is essential for anybody working in these enterprises.

Aluminum profiles come in different shapes and sizes, including rectangular, square, and round. They are ordinarily expelled, an interaction that includes pushing the warmed aluminum through a bite the dust to make the ideal shape. This assembling method takes into consideration the development of mind boggling profiles with exact aspects.

One of the critical benefits of aluminum profiles is their flexibility. They can be redone to meet explicit prerequisites, making them ideal for many applications. For example, in the development business, aluminum profiles are usually utilized for window outlines, entryway outlines, drapery walls, and underlying parts. Their lightweight nature makes them simple to deal with and introduce, while their consumption opposition guarantees long haul sturdiness.

In the auto business, aluminum profiles are utilized for different purposes, for example, undercarriage parts, body designs, and intensity exchangers. The lightweight idea of aluminum profiles adds to eco-friendliness and decreases the general load of vehicles, prompting further developed execution. Furthermore, aluminum profiles offer great warm conductivity, which is useful for heat dissemination in auto applications.

Aeronautic trade additionally intensely depends on aluminum profiles for airplane structures. The high solidarity to-weight proportion of aluminum goes with it an optimal decision for developing lightweight yet strong parts. Aluminum profiles are utilized in the fuselage, wings, and other underlying components of airplane, adding to eco-friendliness and in general execution.

Producing industry likewise uses aluminum profiles for a large number of utilizations, for example, transport frameworks, machine edges, and nooks. The flexibility of aluminum profiles considers simple mix into existing frameworks and the making of altered arrangements. Their high strength and protection from consumption make them reasonable for requesting modern conditions.

Design Considerations for ATE

With regards to planning mechanized test hardware (ATE), there are a few significant contemplations to remember. One vital perspective is the determination of the right materials for development, with a particular spotlight on aluminum profiles.

Aluminum profiles offer various benefits in ATE plan. As a matter of some importance, aluminum is a lightweight material, making it ideal for developing hardware that should be versatile or effectively flexibility. The utilization of aluminum profiles guarantees that the ATE stays light and simple to ship, without settling for less on strength and sturdiness.

Furthermore, aluminum profiles give fantastic warm conductivity. This is fundamental in ATE plan, as numerous electronic parts produce heat during activity. By utilizing aluminum profiles, intensity can be effectively dispersed, forestalling overheating and guaranteeing the hardware performs ideally.

One more advantage of aluminum profiles is their flexibility. They can be handily altered and adjusted to meet explicit plan prerequisites. This adaptability considers the making of mind boggling and complicated structures, guaranteeing that the ATE is custom-made to the necessities of the application.

Besides, aluminum profiles offer magnificent erosion obstruction. This is urgent in ATE plan, as the hardware might be presented to different natural circumstances or synthetic substances. By utilizing consumption safe aluminum profiles, the life expectancy of the ATE can be delayed, decreasing the requirement for regular fixes or substitutions.

As far as Website design enhancement streamlining, referencing the watchwords "Aluminum Profiles" all through the article paragraph is significant." The watchword thickness ought to be around 3%, guaranteeing that the article is advanced for web search tools. By integrating these watchwords normally into the substance, the article will rank higher in important list items, drawing in additional perusers and expected clients.

Building ATE with Aluminum Profiles

With regards to building Mechanized Test Gear (ATE), one material that stands apart is aluminum profiles. These flexible and tough profiles offer various advantages that settle on them an astounding decision for developing ATE frameworks.

Aluminum profiles give high strength and solidness, guaranteeing the dependability and life span of the hardware. Their lightweight nature makes them simple to deal with and transport, considering adaptability in plan and establishment. Also, their consumption safe properties make them ideal for ATE frameworks that might be presented to brutal conditions or synthetic substances.

One more benefit of utilizing aluminum profiles is their similarity with different parts and extras. These profiles accompany a scope of normalized spaces and depressions, taking into consideration simple incorporation of various modules and connections. This flexibility empowers architects and planners to make altered ATE frameworks that meet explicit necessities and can be effectively changed or extended from now on.

As far as style, aluminum profiles offer a smooth and current appearance. Their spotless lines and smooth surfaces upgrade the general look of the ATE framework, making an expert and refined impression. Moreover, these profiles can be effectively anodized or painted in various varieties to match the marking or stylish inclinations of the client.

One significant part of building ATE frameworks is guaranteeing appropriate link the board. Aluminum profiles give coordinated answers for link steering and association, assisting with keeping a clean and proficient arrangement. This not just works on the general usefulness and security of the hardware yet in addition works with investigating and upkeep.

Enhancing ATE Performance and Functionality

Upgrading ATE Execution and Usefulness

In the steadily advancing universe of innovation, the interest for more proficient and high-performing Mechanized Test Gear (ATE) keeps on developing. As makers endeavor to further develop their creation processes and guarantee the nature of their items, the requirement for upgraded ATE execution and usefulness becomes principal. One perspective that assumes a significant part in accomplishing this objective is the utilization of Aluminum Profiles.

Aluminum Profiles offer a heap of advantages with regards to ATE plan and development. Their lightweight yet solid nature settles on them an optimal decision for building strong and dependable test frameworks. Furthermore, their fantastic warm conductivity assists in disseminating with warming created during testing, guaranteeing ideal execution significantly under requesting conditions.

Besides, Aluminum Profiles consider adaptable and adaptable plans, empowering the mix of different parts and modules in a conservative and space-effective way. This adaptability additionally reaches out to the customization choices accessible, permitting producers to fit the ATE to their particular requirements. Whether it is obliging different test instruments, making secluded test stages, or integrating specific apparatuses, Aluminum Profiles give the important flexibility.

The consistent reconciliation of parts is additionally upheld by the variety of adornments and fittings accessible for Aluminum Profiles. These incorporate sections, connectors, and latches that work with simple gathering and dismantling, making support and adjustments bother free. Furthermore, the similarity of Aluminum Profiles with a large number of embellishments considers future extensions or overhauls, guaranteeing a savvy and versatile answer for developing testing prerequisites.

One more striking benefit of Aluminum Profiles is their similarity with different assembling processes. Whether it is machining, welding, or bowing, Aluminum Profiles offer straightforwardness and adaptability during creation, bringing about more limited lead times and expanded effectiveness. This similarity likewise reaches out to the coordination of link the executives arrangements, empowering coordinated and productive directing of links inside the ATE arrangement.

Maintenance and Upkeep of ATE

Support and upkeep of ATE (Robotized Test Gear) is significant for guaranteeing the smooth activity and life span of these super advanced gadgets. ATE assumes a huge part in different businesses, including hardware, auto, and media communications, by performing mechanized testing and examination of electronic parts and frameworks. To expand the proficiency and exactness of ATE, legitimate upkeep rehearses should be followed.

One critical part of ATE upkeep is the ordinary cleaning and investigation of aluminum profiles, which are basic parts of these gear. Aluminum profiles offer primary help and soundness to the ATE structure. After some time, residue, trash, and different impurities can gather on the profiles, prompting potential execution issues. In this manner, it is important to clean the aluminum profiles occasionally to forestall any block to the smooth working of ATE.

To clean the aluminum profiles, a delicate material or brush can be utilized to eliminate the collected soil and residue. It is fundamental to try not to utilize rough materials or cruel synthetics that might make harm the profiles' surface. A gentle cleanser blended in with water can be applied to the material or brush for successful cleaning. Subsequent to cleaning, the profiles ought to be entirely dried to forestall any dampness related harm.

As well as cleaning, standard investigation of the aluminum profiles is essential to identify any indications of wear, erosion, or different harms. Any apparent breaks or disfigurements ought to be addressed quickly to forestall further weakening. On the off chance that essential, substitution of the harmed profiles ought to be completed to keep up with the primary respectability of the ATE.

Aside from the aluminum profiles, different parts of ATE additionally require customary upkeep. This incorporates checking and adjusting the sensors, connectors, and circuit sheets. A complete support timetable ought to be laid out, illustrating the recurrence of investigations and any fundamental fixes or substitutions.

Appropriate support of ATE guarantees ideal execution as well as expands its life expectancy. By following the suggested support rehearses, organizations can limit free time, decrease fix costs, and work on in general efficiency. Organizations really must focus on ATE support and designate assets appropriately to receive the rewards of solid and proficient mechanized testing.

Conclusion

In conclusion, aluminum profiles play a significant role in various industries due to their versatility, strength, and lightweight properties. Understanding the different types and applications of aluminum profiles is essential for maximizing their benefits. Whether it is in construction, automotive, aerospace, or manufacturing, aluminum profiles offer numerous advantages and contribute to the overall efficiency and performance of different products and systems. When designing ATE (Automated Test Equipment), careful consideration should be given to the selection of materials. Aluminum profiles offer lightweight construction, excellent thermal conductivity, versatility, and corrosion resistance, making them a preferred choice for engineers and designers. By incorporating aluminum profiles into the design, manufacturers can create reliable, durable, and visually appealing ATE systems that meet the needs of their clients. The maintenance and upkeep of ATE, including regular cleaning and inspection of aluminum profiles, is essential for its smooth operation and longevity. Proper maintenance practices ensure optimal performance, minimize downtime, and improve productivity for businesses relying on automated testing equipment.