This article provides an in-depth analysis of the cost factors for aluminum profiles and offers effective strategies for cost reduction. It explores the different types of aluminum profiles, their applications, and benefits. The key cost factors including material cost, production processes, market demand, transportation, and overhead costs are discussed. The article also presents cost reduction strategies such as negotiating contracts with suppliers, optimizing production processes, and exploring alternative procurement options. Real-life examples are included to illustrate the effectiveness of these strategies. By understanding the cost factors and adopting innovative cost-saving measures, companies can enhance their operations, improve efficiency, and gain a competitive edge.

Understanding Aluminum Profiles

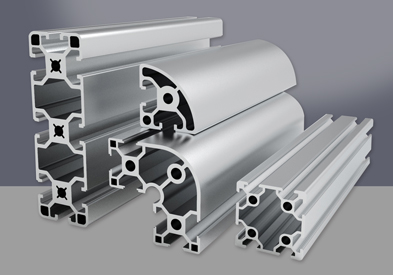

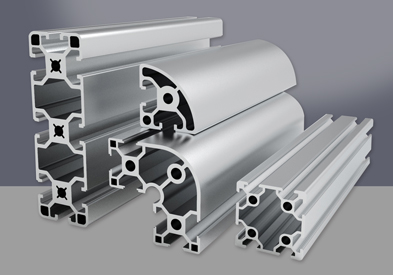

Aluminum profiles are a fundamental part in different enterprises, offering flexibility and sturdiness in many applications. These profiles are made through the expulsion interaction, where aluminum compound is warmed and constrained through a bite the dust to make the ideal shape. Understanding the attributes and advantages of aluminum profiles can assist organizations with settling on informed conclusions about integrating them into their tasks.

One of the critical benefits of aluminum profiles is their lightweight nature. Contrasted with different materials like steel, aluminum is essentially lighter, making it more savvy and simpler to deal with during establishment. Furthermore, aluminum profiles offer fantastic erosion opposition, making them ideal for outside applications where openness to cruel weather patterns is a worry.

One more advantage of aluminum profiles is their high solidarity to-weight proportion. Notwithstanding being lightweight, aluminum profiles have astounding strength, permitting them to endure weighty loads and give primary solidness. This strength is additionally improved by the expulsion cycle, which considers the production of complicated shapes and complex plans.

Aluminum profiles likewise offer extraordinary warm conductivity. This property makes them exceptionally appropriate for applications where heat scattering is critical, for example, in the assembling of intensity sinks for electronic gadgets. The capacity of aluminum to productively move heat forestalls the collection of unnecessary intensity, subsequently expanding the life expectancy and working on the presentation of the hardware.

Notwithstanding their useful characteristics, aluminum profiles likewise give stylish allure. They can be handily tweaked and completed to accomplish different surfaces, varieties, and surface medicines. This adaptability permits organizations to make outwardly engaging items and designs that line up with their image picture.

Price Factors for Aluminum Profiles

With regards to buying aluminum profiles, there are a few value elements to consider. These elements can extraordinarily impact the expense and at last decide the worth you get from your buy. Understanding these value variables will assist you with settling on an educated choice and guarantee that you are getting the most ideal arrangement.

One of the fundamental cost factors for aluminum profiles is the grade of the material. Aluminum profiles come in different grades, each with its own arrangement of qualities and properties. Higher-grade aluminum profiles frequently come at a greater expense because of their prevalent quality and execution. These profiles are commonly more strong, impervious to consumption, and have a more drawn out life expectancy. In any case, in the event that your task doesn't need the utilization of high-grade aluminum profiles, settling on a lower grade can assist you with saving money on costs without settling on usefulness.

Another significant cost factor is the size and state of the aluminum profiles. Custom or particular profiles might require extra assembling processes, which can build the general expense. Standard profiles, then again, are promptly accessible and frequently more reasonable. Furthermore, the length and thickness of the profiles can likewise influence the cost. Longer and thicker profiles commonly cost more because of the expanded measure of natural substance expected for their creation.

Besides, the amount of aluminum profiles required for your task can influence the cost. Mass requests frequently bring about lower per unit costs, as producers can exploit economies of scale. In any case, on the off chance that you just require a little amount of profiles, you might need to follow through on a greater expense because of the extra dealing with and arrangement costs included.

Also, the surface completion and treatment of the aluminum profiles can impact the cost. Profiles with specific completions, for example, anodizing or powder covering, might be more costly than crude or untreated profiles. These completions not just improve the tasteful allure of the profiles yet in addition give added assurance against mileage.

In conclusion, the market interest and accessibility of aluminum profiles can affect the cost. In the event that there is a popularity for aluminum profiles, costs might build because of restricted supply. Then again, in the event that the market is soaked with profiles, costs might be more aggressive.

Strategies for Cost Reduction

Methodologies for Cost Decrease

In the present cutthroat business scene, finding viable techniques for cost decrease has turned into a main concern for some organizations. One key region where cost-saving open doors can be found is in the obtaining and use of materials. Aluminum profiles have arisen as a famous decision for different enterprises because of their flexibility and cost-viability.

By integrating aluminum profiles into their tasks, organizations can accomplish huge expense reserve funds. These profiles are lightweight yet solid, making them ideal for a large number of uses. From development and car enterprises to aviation and gadgets, aluminum profiles offer financially savvy arrangements without settling for less on quality.

One methodology for cost decrease is to advance the plan and creation process by using aluminum profiles. By working intimately with providers and makers, organizations can make redid profiles that meet their particular necessities. This aides in diminishing material waste as well as limits the requirement for extra handling steps, eventually bringing about cost reserve funds.

One more method for accomplishing cost decrease is using aluminum profiles in item improvement. These profiles offer plan adaptability, taking into account the making of intricate shapes and designs. By utilizing this flexibility, organizations can lessen the quantity of parts required and improve on the gathering system. This prompts lower creation costs and expanded effectiveness.

Besides, aluminum profiles are exceptionally recyclable, making them a harmless to the ecosystem and financially savvy decision. By executing reusing programs and using reused aluminum, organizations can diminish their material expenses while limiting their carbon impression. This lines up with supportable strategic approaches as well as helps in accomplishing long haul cost reserve funds.

Case Studies and Examples

With regards to understanding the viability and effect of specific methodologies or strategies, contextual investigations and models assume a vital part. These genuine models give significant bits of knowledge into the reasonable application and outcome of different strategies. Whether it's in the field of business, showcasing, or some other industry, contextual analyses and models act as unmistakable proof that can direct navigation and rouse new methodologies.

One region where contextual analyses and models are especially important is in the domain of aluminum profiles. These flexible and solid materials have become progressively well known in a great many ventures, from development to transportation. Understanding how various associations have used aluminum profiles can reveal insight into their advantages and likely applications.

For example, a contextual analysis could exhibit how a development organization effectively coordinated aluminum profiles into their undertakings, bringing about better primary honesty and cost reserve funds. By featuring the particular difficulties confronted and the creative arrangements carried out, this contextual investigation exhibits the worth of aluminum profiles as well as gives a plan to others to follow.

Essentially, instances of how aluminum profiles have been used in the car business can uncover their job in upgrading eco-friendliness, diminishing vehicle weight, and working on by and large execution. Such models can move other auto makers to investigate the capability of aluminum profiles and embrace comparative procedures.

Additionally, contextual analyses and models can likewise feature the headways and developments in the assembling cycles of aluminum profiles. By analyzing the examples of overcoming adversity of organizations that have executed cutting edge advancements and methods, others in the business can gain from their encounters and remain at the front line of development.

Conclusion

In conclusion, understanding aluminum profiles is crucial for businesses looking to capitalize on their numerous advantages. These profiles offer benefits such as lightweight construction, corrosion resistance, high strength-to-weight ratio, and thermal conductivity. By incorporating aluminum profiles into their projects, businesses can enhance performance, durability, and visual appeal. When considering the price factors for aluminum profiles, it is important to evaluate factors such as grade, size, quantity, surface finish, and market demand. By carefully assessing these factors, businesses can make informed decisions and find the best aluminum profiles that meet their project requirements and budget. Incorporating aluminum profiles into business operations can also be a strategic move to achieve cost reduction by optimizing design and production processes, leveraging the versatility of aluminum profiles in product development, and embracing recycling initiatives. Case studies and examples are valuable tools in understanding the practical applications and benefits of aluminum profiles. They can guide decision-making, inspire innovation, and promote the adoption of aluminum profiles in various industries.